-

Date:2025-12-18

-

Page View:99

An ultrasonic level transmitter is a non-contact level measurement device that is widely used for distance measurement of liquids, bulk materials, and solids. Unlike traditional contact-type level sensors, ultrasonic level transmitter accurately measure distance by transmitting ultrasonic waves and receiving the reflected echoes. Because they do not require direct contact with the measured object, they can operate reliably in environments involving liquids, powders, and granular materials.

How Does an Ultrasonic Level Transmitter Work?

The operating principle of an ultrasonic level transmitter is based on the propagation characteristics of ultrasonic waves in a medium. Liquid level is determined by transmitting and receiving ultrasonic signals. The working principle can be summarized as follows:

An ultrasonic level transmitter consists of an ultrasonic transducer (probe) and a transmitter. During operation, the transducer emits ultrasonic pulses at a specific frequency. These high-frequency pulses travel at the speed of sound and are reflected when they encounter the surface of the measured medium (such as a liquid surface). The reflected signal is then received by the same transducer and converted into an electrical signal.

The time required for the ultrasonic wave to travel from transmission to reception (the transit time) is proportional to the distance between the transducer and the surface of the measured medium. Based on the relationship between the sound velocity C and the transit time t, the distance can be calculated using the following formula:

S = C × t / 2

Where:

S is the distance from the transducer to the liquid surface

C is the propagation speed of the ultrasonic wave in the medium

t is the time from pulse transmission to echo reception

Classification of Ultrasonic Level Transmitters

Based on structural design, ultrasonic level transmitters can be divided into two types: integral (compact) and remote (separate).

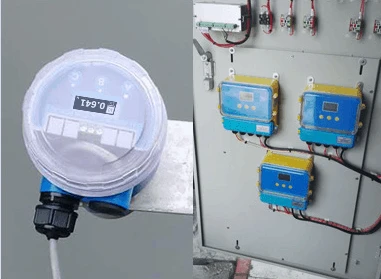

Integral Ultrasonic Level Transmitter

An integral ultrasonic level transmitter integrates the ultrasonic probe, signal processing unit, and display into a single device. All measurement and control functions are completed within one enclosure.

Remote Ultrasonic Level Transmitter

A remote ultrasonic level transmitter consists of a separately mounted probe and a signal processing unit. The probe is installed at the measurement point, while the signal processing unit can be mounted in a control room or another convenient location away from the measuring point. The two components are connected by a cable.

What Are the Advantages and Disadvantages of Ultrasonic Level Transmitter?

Advantages of Ultrasonic Level Transmitters

1. Non-contact measurement

The sensor does not come into direct contact with the measured medium, so it does not contaminate the liquid. It is also not affected by corrosion or wear from the process fluid, making it suitable for corrosive and chemical environments.

2. Strong adaptability

Ultrasonic level transmitters are suitable for various types of liquids and containers, such as storage tanks, pipelines, and chemical reactors. They can operate reliably in harsh conditions including high temperature, high pressure, and corrosive environments, and are largely unaffected by medium viscosity, density, or humidity.

3. Multiple measuring ranges and material options

Ultrasonic liquid level sensor are available in different measuring ranges, such as 5 m, 10 m, and 15 m, to meet diverse industrial requirements. Probe materials such as corrosion-resistant PVDF ensure reliable measurement in aggressive liquids and environments.

4. High resistance to interference

Ultrasonic liquid level sensor offer strong immunity to interference and can operate stably in environments with strong electromagnetic fields, such as substations and transmission towers.

5. Easy installation and maintenance

With a simple structure, compact size, and light weight, ultrasonic level transmitters are easy to install and maintain. Because they do not contact the process fluid, installation does not require special consideration of corrosion or contamination.

6. Real-time monitoring and automation

Ultrasonic liquid level sensor provide real-time level measurement and can communicate with host systems or PLCs to enable remote monitoring and automated control.

Limitations of Ultrasonic Level Transmitters

1. Presence of a blind zone

The blind zone refers to the area that cannot be measured by the instrument. During ultrasonic pulse transmission, a small region near the transducer cannot receive reflected signals. The size of the blind zone depends on the measuring range: shorter ranges result in smaller blind zones, while longer ranges increase the blind zone.

2. Sensitivity to mist, dust, foam, and volatile media

Ultrasonic liquid level sensor are not suitable for applications with heavy mist, dust, media that generate large amounts of foam, or highly volatile substances. These conditions can absorb or disrupt ultrasonic signals, leading to signal loss and reduced accuracy.

3. Sensitivity to obstacles

Because ultrasonic level measurement relies on sound wave reflection, obstacles within the measuring path can interfere with signal transmission, causing signal loss or measurement errors.

4. Measurement affected by temperature

Medium temperature is a key factor influencing ultrasonic level transmitter performance. When the temperature inside a closed vessel differs from the ambient environment, condensation may form on the probe, reducing measurement accuracy. During installation, a compressed air purge can be used to keep the probe dry and prevent accuracy degradation caused by condensation.