-

Date:2026-01-04

-

Page View:84

In wastewater flow measurement, electromagnetic flow meters are widely regarded as the superior option for several compelling reasons. First, their operating principle is based on Faraday’s law of electromagnetic induction and is specifically suited for conductive liquids such as wastewater. This allows them to accurately detect the movement of charged particles in the fluid, ensuring precise measurement of both flow velocity and flow rate.

Second, electromagnetic flow meters offer excellent corrosion resistance. The use of insulating liners combined with chemically passivated electrode surfaces enables them to withstand the corrosive nature of wastewater with ease.

In addition, their measurement accuracy is not affected by changes in the fluid’s physical properties. Variations in wastewater density, viscosity, or temperature do not compromise performance, allowing the meter to maintain high accuracy under fluctuating operating conditions.

Why Are Electromagnetic Flow Meters Commonly Used for Wastewater Measurement?

1. Advantages in Large-Diameter Applications

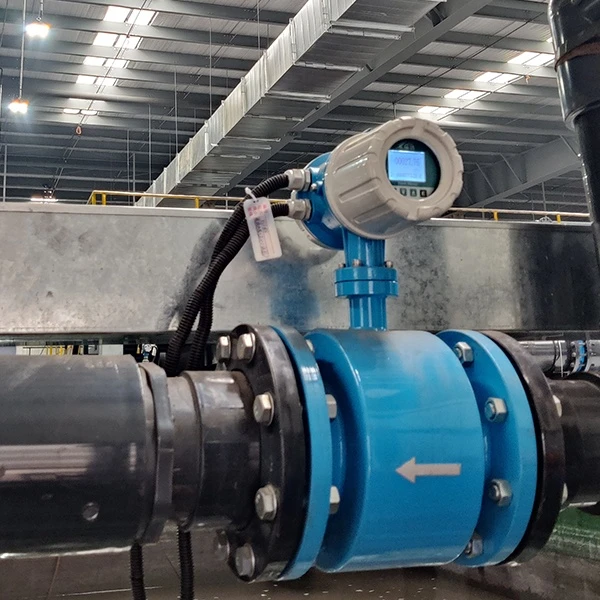

In wastewater treatment plants, main inlet/outlet pipelines and discharge lines usually have large diameters (DN300 and above). Electromagnetic flow meters can easily handle large-pipe flow measurement through remote-mounted transmitters or insertion-type designs.

2. Strong Adaptability to Complex Media

Wastewater has a complex composition and may contain solid particles, fibers, and air bubbles. With no flow-obstructing components inside the measuring tube, electromagnetic flow meters cause no pressure loss and perform well in high-solids applications. Their excellent corrosion resistance—enabled by various liner and electrode materials such as PTFE, rubber, and Hastelloy—also makes them suitable for acidic or alkaline wastewater.

3. Full-Bore, Non-Clogging Design

Electromagnetic flow meters have no moving mechanical parts, and the measuring tube is straight-through, allowing wastewater to pass freely without clogging. This is critical in wastewater applications, where fibers and sand are common. In contrast, turbine or orifice flow meters are much more prone to blockage, which can affect accuracy or even damage the instrument.

4. High Accuracy and Stable Performance

Based on Faraday’s law of electromagnetic induction, electromagnetic flow meters can accurately measure flow as long as the liquid has minimal conductivity—a condition typically met by wastewater. Accuracy is usually ±0.5% or better, and measurements are not affected by changes in fluid density, viscosity, or temperature, making them ideal for wastewater with fluctuating flow rates.

5. Low Maintenance Costs

With a simple structure and no moving parts, electromagnetic flow meters offer low failure rates and long service life. Routine maintenance generally involves only periodic inspection of the electrodes and liner.

6. Smart and Easy System Integration

Modern electromagnetic flow meters feature digital signal processing and communication options such as HART, Modbus, or 4–20 mA outputs. They can be seamlessly integrated into wastewater treatment plant automation systems (SCADA or DCS) for remote monitoring and data logging.

Mag Flow Meters for Wastewater Treatment

Sewage Magnetic Flowmeters

Selection Guidelines for Electromagnetic Flow Meters

Although electromagnetic flow meters offer clear advantages in wastewater measurement, the following factors should be considered during selection:

Medium Conductivity: Electromagnetic flow meters require the measured fluid to have sufficient electrical conductivity, typically ≥ 5 μS/cm. If the wastewater conductivity is too low, other types of flow meters may need to be considered.

Liner and Electrode Materials: Select appropriate liner materials (such as rubber or PTFE) and electrode materials (such as stainless steel or Hastelloy) based on the wastewater’s corrosiveness and operating temperature.

Installation Location: Install the meter in a full-pipe section whenever possible to avoid the influence of air bubbles or sediment on measurement accuracy.

Protection Rating: Wastewater environments are usually humid, so meters with a high ingress protection rating, such as IP68, are recommended.

In addition to measuring the volumetric flow of general conductive liquids, electromagnetic flow meters are also suitable for highly corrosive fluids such as strong acids and alkalis, as well as homogeneous liquid–solid suspensions like sludge, slurry, ore pulp, and paper pulp. As a result, they are widely used in industries including chemical processing, petroleum, pharmaceuticals, and environmental protection.

If you encounter any challenges in wastewater flow measurement, please feel free to contact us—we are always ready to support you.