-

Date:2025-08-28

-

Page View:278

Liquid flow meters are essential devices used across various industries to measure the flow rate of liquids. To ensure accurate measurement and monitoring of liquid flow, it is first necessary to fully understand the operating conditions, physical and chemical properties, and measurement range of the medium being measured. Secondly, it is important to be familiar with the working principles, selection criteria, advantages, and suitable applications of different types of liquid flow meters.

Among flow measurement instruments, liquid flow meters are widely applied. Some of the most commonly used devices include orifice plate flow meters, rotameter (variable area) flow meters, turbine flow meters, vortex flow meters, electromagnetic flow meters, and ultrasonic flow meters. Electromagnetic and ultrasonic flow meters, as products of non-intrusive continuous measurement technology, offer high accuracy and stability. They experience no wear or contamination due to contact, are relatively simple to operate and maintain, and avoid pressure loss during the measurement process.

Classification of Liquid Flow Meters

Electromagnetic Flow Meter: Based on Faraday's law of electromagnetic induction, it utilizes a conductor cutting through magnetic lines of force within a magnetic field to generate an induced electromotive force at both ends of the conductor. This type of flow meter is suitable for conductive liquid media.

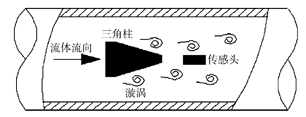

Vortex Flow Meter: It operates by utilizing the Kármán vortex street effect generated when fluid passes a bluff body. The frequency of the vortices is proportional to the flow velocity. This type of meter is suitable for monitoring the flow of single-phase, clean, non-pulsating, low-vibration fluids with a Reynolds number between 2×10⁴ and 7×10⁶, such as low-viscosity gases, steam, and liquids.

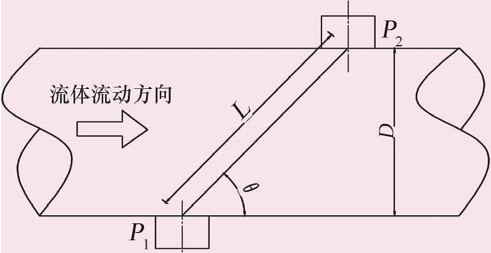

Ultrasonic Flow Meter: It works by detecting the influence of fluid flow on internal ultrasonic signals. Flow information is obtained by analyzing changes in the acoustic signals. It is well-suited for measuring flow in large-diameter pipes and for corrosive media.

Turbine Flow Meter: Fluid causes the turbine blades to rotate at a speed proportional to the flow velocity. The rotational speed is detected by an electromagnetic pickup to calculate the flow rate. It is suitable for monitoring the flow of clean, low-viscosity liquids.

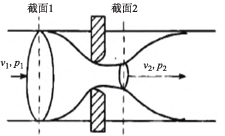

Orifice Plate Flow Meter: Fluid passing through the orifice plate creates a differential pressure. A transmitter converts this differential pressure signal into a corresponding electrical signal and sends it to a flow instrument, which then calculates the instantaneous or cumulative flow rate of the fluid under standard conditions based on the measured parameters. This instrument has a wide range of applications but suffers from high-pressure loss and elevated maintenance costs.

Variable Area Flow Meter (Rotameter): A float moves up and down within a tapered tube in response to changes in flow rate. The position of the float indicates the corresponding flow value. It is suitable for monitoring low to medium flow rates of clean fluids.

Vortex Flow Meter

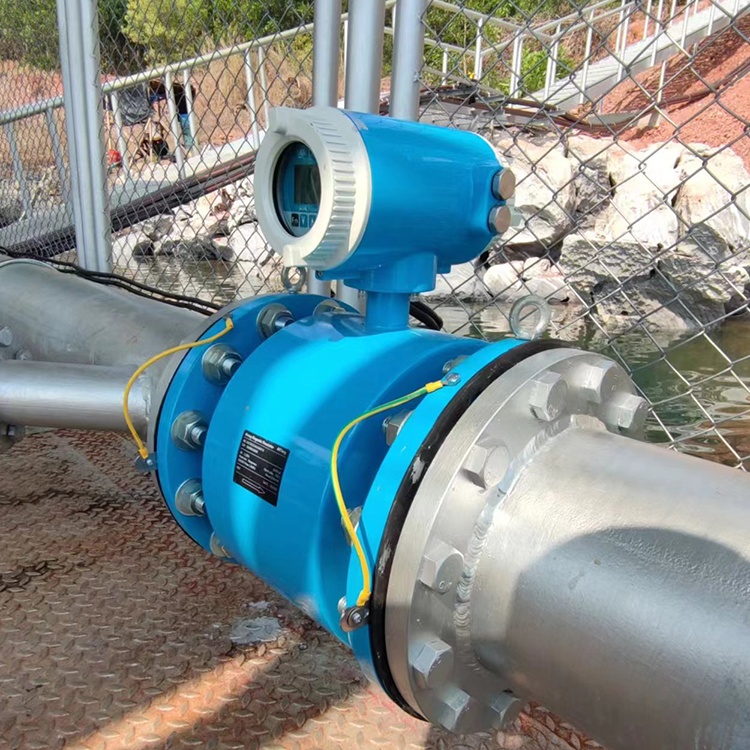

Electromagnetic Flow Meter

Ultrasonic Flow Meter

Working Principle of Liquid Flow Meters

Electromagnetic Flow Meter:

Operates based on Faraday's law of electromagnetic induction. When a conductor moves through a magnetic field and cuts across magnetic flux lines, an electromotive force (EMF) is induced perpendicular to both the magnetic field direction and the direction of motion. The magnitude of this EMF is proportional to the magnetic flux density and the velocity of the motion.

In practice, an electrically conductive liquid flows through a non-magnetic measurement tube perpendicular to the magnetic field. An electrical potential proportional to the flow rate is generated perpendicular to both the flow direction and the magnetic field.

Vortex Flow Meter:

A bluff body (vortex shedder) is placed in the fluid path. As the fluid flows past this body, it alternately generates vortices on either side, known as a Kármán vortex street. Within a specific flow range, the frequency of vortex shedding is proportional to the average flow velocity in the pipeline.

Ultrasonic Flow Meter:

Ultrasonic waves traveling through a fluid carry information about the fluid's flow velocity. By transmitting and receiving these ultrasonic signals, the flow velocity can be detected, allowing for the calculation of the flow rate.

Turbine Flow Meter:

When fluid flows through the sensor housing, it exerts a force on the turbine blades. Due to the specific angle between the blades and the flow direction, this force generates a rotational torque. This torque is sufficient to overcome friction and fluid resistance, causing the turbine to rotate. Once torque equilibrium is reached, the stable rotational speed of the turbine becomes directly proportional to the flow velocity.

The turbine blades are made of a magnetically permeable material. As they rotate within the magnetic field of a detector (which contains a permanent magnet and a coil), they cut through the magnetic flux lines, causing periodic changes in the magnetic flux through the coil. This induces electrical pulses in the coil.

These pulse signals are amplified and shaped into stable rectangular waves, which can be transmitted to a display instrument to show the instantaneous or cumulative flow rate. Within a specific flow range, the frequency of the pulses is proportional to the instantaneous flow rate of the fluid passing through the sensor.

Orifice Plate Flowmeter:

When the measured medium flows from left to right through the orifice plate throttling device (as shown below), the flow channel suddenly narrows, the flow stream contracts, and the velocity increases from V1 to V2. According to the law of energy conservation, the static pressure of the medium decreases from P1 to P2 before and after the orifice plate. As a result, the flowmeter across the orifice plate generates a static pressure difference (differential pressure) ΔP = P1 − P2. When the conditions of the medium change, the differential pressure before and after the orifice plate also changes accordingly. By measuring this pressure difference, the flow rate can be determined.

Rotameter (Variable Area Flowmeter):

In a vertical tapered tube that widens from bottom to top, a float with a circular cross-section is supported by the hydraulic force of the fluid. The float can freely rise and fall within the tube. Under the combined effect of flow velocity and buoyancy, the float moves up or down until it balances with its own weight. Through magnetic coupling, this position is transmitted to the scale dial to indicate the flow rate.

Applications of Liquid Flow Meters

Liquid flow meters are widely used in various industries, such as:

Slurry and Pulp: Monitoring the flow rate of ore slurry in mineral processing, or black liquor in the paper industry.

Corrosive Chemicals: Measuring and controlling the flow of acid and alkali solutions, salt solutions in chemical plants, and corrosive liquids in electroplating plants; monitoring electrolyte solutions in pharmaceutical production.

Water and Wastewater:

Industrial: Measuring circulation water in cooling systems to ensure stable equipment cooling.

Municipal: Monitoring water flow in city water supply pipelines; measuring inflow and outflow at wastewater treatment plants.

Civil Use: Monitoring irrigation water in farmland; measuring purified water flow in pharmaceutical plants.

Food and Beverage: Monitoring syrup flow in juice production; yeast recovery flow in breweries; flow rate in milk processing pipelines.

Liquid Flow Meter for Flow Measurement

sanitary flowmeter

Selection Principles for Liquid Flow Meters

When selecting a liquid flow meter, it is essential to ensure that the instrument is suitable for the specific application. Accuracy and stability should be carefully considered to guarantee reliable measurement results. In addition, ease of operation and maintenance, as well as cost-effectiveness, are important factors to achieve the best match for your needs.

Identify Medium Characteristics: Consider the conductivity, viscosity, corrosiveness, and solid content of the medium to help determine the most suitable type of flow meter.

Define Operating Parameters: Specify maximum and minimum flow rates, medium temperature and pressure, and pipeline diameter to ensure that the selected flow meter’s size and range match actual requirements.

Verify Functional Requirements: Determine the required measurement accuracy, whether portability or handheld use is needed, and the type of output signals required, so the flow meter aligns with practical applications.

Evaluate Environmental Conditions: Ambient temperature, humidity, electromagnetic interference, safety requirements, explosion-proof measures, and pipeline vibration can all affect performance, so a thorough assessment is necessary.

Balance Cost and Budget: Consider both purchase and operating costs to ensure an optimal balance of performance and affordability.

Leverage Manufacturer Support: Clearly communicate your actual requirements and consult with the manufacturer’s technical team to efficiently select the most suitable flow meter for your application.

By analyzing these dimensions systematically, you can effectively match the demands of industrial liquid flow measurement, ensuring that the chosen flow meter achieves the best balance between accuracy, reliability, and cost-efficiency, while adapting well to real operating conditions.

Installation and Maintenance of Liquid Flow Meters

Proper installation and regular maintenance are essential for achieving optimal performance and extending the service life of liquid flow meters. General guidelines include:

Install the flow meter according to the manufacturer’s instructions, ensuring correct orientation and alignment.

Calibrate the flow meter regularly to maintain accuracy and adjust settings based on any system changes.

Clean the flow meter periodically to remove debris or buildup that could affect its performance.

Monitor for leaks or damage and address issues promptly to prevent inaccurate readings or system failures.

Liquid flow meters are vital instruments for measuring and monitoring liquid flow across industries. They provide precise measurements, process optimization, and resource management, ensuring efficient operations and compliance with industry standards. By understanding the types, working principles, applications, and benefits of liquid flow meters, professionals can make informed decisions when selecting and applying these devices in their respective fields.