-

Date:2025-08-19

-

Page View:328

In the food and beverage industry, strict quality standards and rigorous operating conditions must be implemented to ensure product quality and consumer safety. The sensors used must be able to withstand various media, high temperatures, temperature fluctuations, and frequent cleaning to ensure smooth operation and process reliability.

High-protection-rated flow meters are not only essential for ensuring the integrity of production processes and product quality but also serve as a crucial tool for driving production optimization.

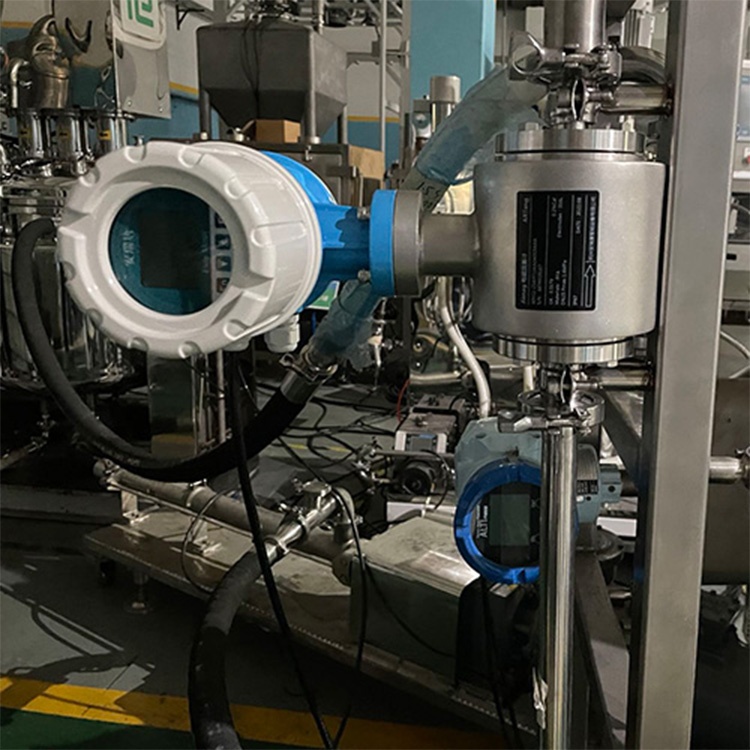

ARTang has launched the Aimag H hygienic magnetic flow meters. Compared to traditional electromagnetic flow meters, ARTang has achieved technological breakthroughs in multiple aspects, significantly enhancing user experience. The large-screen display and LED ring indicator lights provide an intuitive visual representation of key data and equipment status. The fully stainless steel housing design enhances durability and corrosion resistance, allowing for easy cleaning and compliance with food-grade hygiene standards.

Advantages of the Hygienic Magnetic Flow Meter

1. Hygienic design compliant with industry standards

The ARTang food-grade electromagnetic flow meter is designed with the hygiene requirements of the food industry in mind, utilizing hygienic lining materials and clamp connections. This design not only ensures that the medium is not easily contaminated during use but also effectively prevents the accumulation of residual measured fluid in the measuring tube. Additionally, the flowmeter is equipped with a stainless steel housing and stainless steel clamp connections, enabling quick disassembly and cleaning, further enhancing hygiene standards.

2. High-precision measurement, ensuring product quality

The ARTang food-grade electromagnetic flowmeter operates based on Faraday's law of electromagnetic induction, calculating flow rate by measuring the induced electromotive force generated when conductive liquid cuts through magnetic field lines in a magnetic field. This measurement method is unaffected by changes in fluid density, viscosity, temperature, pressure, and conductivity, thereby achieving the highest measurement accuracy. In food processing, high-precision flow measurement ensures accurate raw material ratios, thereby safeguarding product quality and taste.

3. Pressure-loss-free design, reducing energy consumption

Compared to traditional flow measurement instruments, the ARTang hygienic magnetic flow meter has no obstructing moving parts inside the measuring tube, thus avoiding pressure loss. This pressure-loss-free design not only reduces energy consumption but also minimizes fluid wear on the measuring components, thereby extending the service life of the equipment.

4. Intelligent communication functionality for remote monitoring

The ARTang food-grade electromagnetic flowmeter supports multiple communication protocols, including HART, PROFIBUS DP/PA, Foundation Fieldbus (FF), and MODBUS RS485. These communication protocols enable seamless integration with various process control systems, facilitating remote monitoring and data analysis. Through remote monitoring, businesses can access real-time flow data, adjust production parameters promptly, and enhance production efficiency.

5. Easy installation and maintenance, reducing operational costs

The ARTang hygienic magnetic flow meter excels in installation and maintenance. Its simple and reliable structure, with no moving parts, makes the installation and commissioning process relatively straightforward. Additionally, the flow meter's self-calibration function allows for online verification of measurement accuracy without interrupting the process flow, thereby reducing maintenance costs.

Customized for the food and beverage industry

High-precision process data monitoring ensures product consistency and quality in critical stages such as mixing and packaging; constructed with all-stainless steel materials and integrated capacitive touch buttons, it eliminates hygiene dead zones, is resistant to contamination, and easy to clean, meeting food-grade hygiene standards; suitable for the production processes of liquid foods such as milk, juice, soft drinks, yogurt, beer, and wine, as well as monitoring CIP cleaning solutions. In dairy production, the ARTang hygienic magnetic flow meter precisely monitors changes in milk flow, ensuring efficient and consistent pasteurization and packaging processes. In beer brewing, the innovative design without mechanical components provides a more reliable solution for measuring media such as hot water, wort, and beer. In wine production, the flow meter's high hygiene standards and precise monitoring capabilities help optimize production processes and ensure consistent quality.

Hygienic Magnetic Flow Meter

Food-Grade Electromagnetic Flowmeters

Application of ARTang Food-Grade Electromagnetic Flowmeters

1. Beverage Industry

Nongfu Spring, with 20 years of juice production experience, uses ARTang food-grade electromagnetic flowmeters to precisely mix juice, water, and sugar, ensuring accuracy in conductivity and sugar content addition. Before juice supply, it is heated to 90°C via the heat exchanger of an instant sterilizer and maintained for 20 seconds to ensure quality and shelf life. The hygienic magnetic flow meter monitors flow and ensures the medium reaches the required temperature during this process.

2. CIP - In Corrosive Environments

The dairy industry has achieved precise monitoring of water supply and return flow rates and temperatures by introducing ARTang electromagnetic flow meters, ensuring the critical cleaning temperature requirement of 80°C and enhancing the efficiency of the cleaning process. The ARTang hygienic magnetic flow meter can withstand corrosion from external cleaning agents, avoiding the damage issues associated with traditional sensors.

3. Dairy Industry

The dairy industry has strict requirements for measurement accuracy and hygiene standards. Rely on the ARTang hygienic magnetic flow meter to achieve precise measurements in harsh environments. This flow meter features a compact design and interchangeable components, minimizing maintenance requirements while meeting long-term operational needs. It can withstand SIP cleaning at temperatures up to 144°C and provides stable measurement results even under mechanical stress, significantly reducing the risk of damage to traditional sensors.

4. Personal Care Products

On personal care product production lines, the ARTang hygienic magnetic flow meter is used to precisely control the addition of raw materials such as salt solutions, pigments, and fragrances, ensuring process monitoring during mixing and filling. Its instantaneous flow and cumulative flow output functions ensure smooth production processes and precise product filling. Additionally, during the cleaning phase, the flow meter measures conductivity and temperature to ensure the reliability and efficiency of the cleaning process.

ARTang hygienic magnetic flow meters are widely used in multiple industries, meeting the market's demand for efficient and hygienic flow measurement solutions. ARTang food-grade flow meters come with an industry-leading 2-year warranty and superior after-sales service! Providing leading measurement and control solutions for the food and beverage industry.