-

Date:2025-08-05

-

Page View:271

Pressure transducers play a crucial role in various industries, enabling the measurement and monitoring of pressure in different systems and processes. From automotive applications to industrial manufacturing and aerospace engineering, pressure transducers provide accurate and reliable data that is essential for efficient operations.

What is a Pressure Transducer?

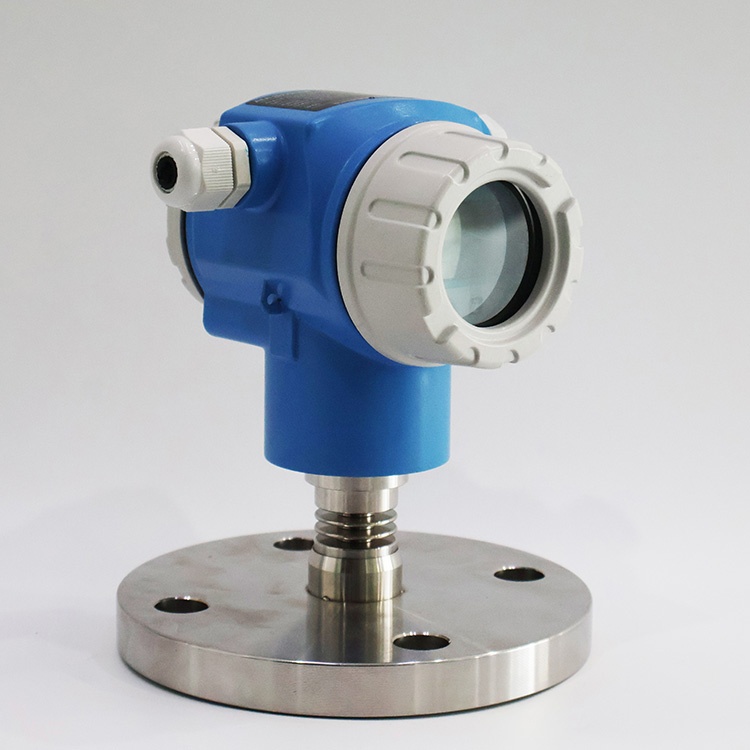

A pressure transducer is a device that converts a physical pressure measurement into an electrical signal. It is a vital component in various systems where pressure monitoring is crucial, such as hydraulic systems, pneumatic systems, and HVAC systems. Pressure transducers are designed to withstand and measure pressure changes accurately and reliably.

Types of Pressure Transducers

To cover a wide range of industrial or laboratory applications, what are the different types of pressure transducer you may need?The three main types of pressure transducers are absolute, differential and gauge. What type of transducer to purchase in any given situation depends entirely on the specifics of your application and the type of reading required.

Absolute Pressure Sensors

Absolute pressure sensors are a type of vacuum pressure sensor. They always read relative to zero and have a positive output value, whereas other types of sensors can be positive or negative.

They are well suited for measuring barometric pressure in barometer-critical applications such as weather monitoring or navigation altitude detection. Barometric pressure sensors rely on establishing a reference value from an absolute vacuum for reliable readings.

For barometric pressure detection, this is critical because the pressure of a gas is inversely proportional to its temperature. Without a perfect vacuum as a zero reference, absolute pressure readings will vary due to thermal fluctuations.

Differential Pressure Sensors

Differential pressure sensors measure the change in pressure between two points in a system. This is important for checking the correct operation of various aspects of the system, such as bleeder valves or flow rates.

Differential pressure transducers vary in specifications, but most can measure pressure on both sides of a single diaphragm in the sensor element. Depending on how these pressures deflect the diaphragm, the reading on either side can be positive or negative.

Other setups can also be created to measure the difference in pressure between two or more independent sensor devices that are located in remote locations and connected by signals from their internal electronics.

Gauge Pressure Sensors

Gauge pressure sensors are relative pressure sensors. Typically, they are used to measure the relative difference between local atmospheric pressure and the pressure level at a given location in another system.

Applications include checking the level of a vented tank, operating a sphygmomanometer, or controlling the required speed and power of a vacuum pump. In both cases, the difference in real-time atmospheric pressure around the system will affect the required calculations and readings.

Many gauge pressure sensors rely on a thin film connected to a resistor or similar electronic component that registers the deflection force as a change in the output value.

Pressure Transducer

Differential Pressure Sensors

Pressure transducers/ sensors

Applications of Pressure Transducer

Pressure transducer are used in a wide range of industries and various applications. Some notable applications include:

1. Industrial automation: for monitoring and controlling pressure parameters in industrial processes, such as boiler pressure, pipeline pressure, hydraulic system pressure, etc., to ensure the safety and stability of the production process.

2. Automotive electronics: used to monitor tire pressure, fuel pressure, brake pressure, etc. of automobiles to improve the safety and performance of automobiles.

3. Aerospace: Used in aircraft and spacecraft to measure atmospheric pressure, fuel pressure, hydraulic system pressure, etc., to ensure flight safety and performance.

4. Environmental monitoring: used to monitor atmospheric pressure, water pressure and other environmental parameters, to provide data support for environmental monitoring and weather forecasting.

How to Select the Right Pressure Transducer

Selecting the correct pressure transducer for a particular application requires consideration of several factors:

1. Pressure Range

The transducer must be able to measure the pressure range expected in the application. Selecting a sensor with too narrow a range may result in inaccurate readings or damage to the sensor, while selecting a sensor with too wide a range may lack the necessary sensitivity.

2. Accuracy

The required accuracy of a sensor depends on the application. For critical applications such as medical devices or aerospace systems, high accuracy is essential. In less critical applications, a less accurate sensor may be sufficient.

3. Environmental conditions

The operating environment can significantly affect sensor selection. Factors to consider include temperature, humidity, exposure to corrosive substances and electromagnetic interference. Some sensors are designed for harsh environments while others are better suited for controlled conditions.

4. Output Signals

Consideration should be given to the type of output signal (analog or digital) required by the control system. Some applications may require specific signal types such as 4-20mA, 0-5V, or digital communication protocols (e.g., I2C or SPI).

5. Size and Shape

The physical size and shape factors of a sensor can be important, especially in applications where space is limited. Miniature sensors can be used in compact spaces, while larger sensors can provide additional functionality or ruggedness.

6. Compatibility

Sensors must be compatible with existing systems in terms of electrical connections, communication protocols, and mechanical fittings. Compatibility issues may result in additional costs or the need for system modifications.

ARTang pressure transducer are known for their high accuracy and stability in harsh industrial environments. It typically consists of a sensing element that detects pressure and converts it to an electrical output, such as a voltage or current signal.

These sensors can be used in a wide range of industries such as oil and gas, chemical processing, water treatment, heating, ventilation and air conditioning (HVAC), and many others. They are commonly used in process control, monitoring systems, and data acquisition.

ARTang offers pressure transducer in a variety of sizes and features to meet specific application needs. These needs may include pressure range, accuracy level, output signal, temperature range, and compatibility with different fluids.

When selecting an ARTang pressure transducer, it is important to consider factors such as the pressure range to be measured, the required accuracy, environmental conditions, and any specific industry standards or regulations that must be met.