-

Date:2025-08-07

-

Page View:271

Differential pressure transmitter is a transmitter to measure the pressure difference between the two ends of the transmitter, and general pressure transmitter is different, it has two input pressure interface, but also will be divided into positive and negative pressure end, only when the positive pressure end of the pressure is greater than the negative pressure end of the pressure can be measured.

Differential Pressure Transmitter Working Principle

Differential pressure from both sides of the conduit to act directly on the isolation diaphragm located on both sides of the transmitter's sensor, through the diaphragm within the sealing fluid to the measuring element, the measuring element will be measured by the conversion of differential pressure signals into electrical signals corresponding to the electrical signal is transmitted to the converter, electrical signals through the converter amplification and processing of the standard electrical signals after the output.

Components of a Differential Pressure Transmitter

Differential pressure transmitters consist of several key components. These include:

Diaphragm: The diaphragm is the main sensing element that converts pressure into mechanical deflection.

Pressure Sensors: These sensors detect the deflection of the diaphragm and convert it into an electrical signal.

Transmitter electronics: The transmitter electronics receive signals from the pressure sensors and amplify, condition and convert them into an output signal.

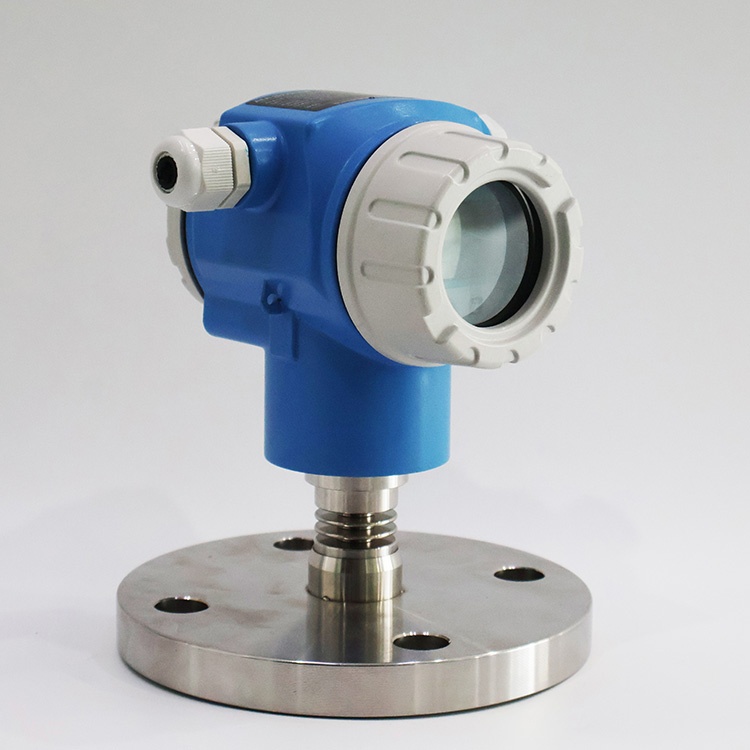

Housing: The housing encases the sensitive components and protects them from external influences.

Process Connections: These connections allow the transmitter to interface with the process or system under test.

Measurement and control of differential pressure transmitters

Differential pressure transmitters are suitable for the following measurement and control situations:

*High temperature viscous media

*Crystallizable media

*Mediums containing solids or suspended particles

*Strongly corrosive or highly toxic media

* Liquid differential pressure transmitter can eliminate the leakage of the pressure conduit to contaminate the surrounding environment; can avoid the use of isolation fluid due to the measurement signal instability and the need to frequently replenish the isolation fluid cumbersome work.

*Continuous, accurate measurement of interface and density

remote transmission device can avoid the mixing of different instantaneous media, so that the measurement results can truly reflect the actual situation of the process changes, even if the use of low-range differential pressure transmitter.

* Higher requirements for hygiene and cleanliness

For example, in food, beverage, pharmaceutical and other industrial production, not only requires the transmitter and the media contact parts to meet the hygiene standards, but also to facilitate the flushing to prevent cross-contamination of different media.

differential pressure transducer

differential pressure transmitter

How to Select a Differential Pressure Transmitter

When selecting a differential pressure transmitter, it is essential to consider various factors such as process requirements, measurement accuracy, and on-site environmental conditions to ensure the long-term stable operation and measurement accuracy of the equipment. The following are key selection criteria:

1. Measurement Range

The selected transmitter should cover the minimum and maximum pressure differentials that may occur in the system. It is recommended to leave a certain safety margin during selection to avoid the transmitter operating at full scale for extended periods, thereby extending its service life.

2. Measurement Accuracy

Determine the required measurement accuracy based on specific application needs. High-precision differential pressure transmitters (e.g., ±0.1% or ±0.2% FS) are suitable for critical process control or energy measurement, while standard control applications can use models with approximately 0.5% FS accuracy.

3. Environmental Adaptability

Ensure that the selected transmitter can withstand the on-site working conditions such as temperature, humidity, vibration, and electromagnetic interference. For outdoor or high-humidity environments, choose products with high protection ratings (e.g., IP65/IP67) or explosion-proof certification.

4. Output Signal Type

Common output types include 4–20 mA (analog signal), HART (with communication), RS485 (Modbus protocol), etc. Select the appropriate signal type based on your control system or PLC requirements to ensure system compatibility.

5. Material Compatibility with the Measured Medium

The parts of the transmitter in contact with the medium (such as diaphragms, flanges, and sensor housings) must be chemically compatible with the measured fluid to prevent corrosion, contamination, or damage to the equipment. Common materials include 316L stainless steel, Hastelloy, and tantalum.

Differential Pressure Transmitter Installation and Maintenance

1. Installation Guidelines: Minimizing Interference and Errors

Pressure Tap Selection: Avoid turbulent areas such as elbows and valves. It is recommended to install the transmitter on a straight section of the pipeline (upstream ≥ 10D, downstream ≥ 5D).

Pressure-Conducting Tube Installation: For liquid media, the tube should slope downward; for gas media, it should slope upward to prevent bubble or condensate buildup.

Grounding and Shielding: Signal cables must use shielded cables and be grounded separately (resistance <4Ω).

2. Maintenance Strategy: Extend Service Life

Routine Inspection: Inspect the diaphragm for deformation and the pressure-conducting tubes for blockages quarterly.

Calibration Cycle: Calibrate every 6 months in high-precision scenarios and every 12 months in general scenarios. Calibration must use a standard pressure source (accuracy ±0.02% FS).

Winter Maintenance: Install insulation layers or electric heating in low-temperature scenarios to prevent medium crystallization from blocking the pressure-conducting tubes.

Difference between pressure transmitter and differential pressure transmitter

Pressure transmitter is the practice of the pressure value is converted into a standardized electrical signal (such as: 0-10VDC) output, while the differential pressure transmitter is compared between the two pressure values of the pressure difference, the difference will be converted into a standardized signal output (the practice is to do the subtraction, and then the output of the difference).

Differential pressure transmitter has two interfaces, the main measurement of the differential pressure between the two ports, pressure transmitter on an interface, measuring gauge pressure or absolute pressure. Parameters that should be provided: Range Comprehensive accuracy Output voltage Supply voltage Operating temperature Threaded connection Signal lead interface and so on.

Pressure transmitter is to measure the pressure of a point, differential pressure transmitter is to measure the pressure difference between two points (high pressure side and low pressure side). If the low pressure side is connected to the atmosphere directly, the differential pressure transmitter can also be used as a pressure transmitter.

What are differential pressure sensors?

Differential pressure sensors measure the difference between 2 absolute pressures p1 and p2 in gases, steam, and liquids. Among other applications they can be found in filter monitoring, level measurement in closed containers, and safety-critical systems. They are often referred to as differential pressure transmitters or differential pressure transducers.

Where are differential pressure sensors used?

Differential pressure sensors are found wherever pressure ratios have to be continuously measured and checked (for example in filter monitoring or flow measurement).