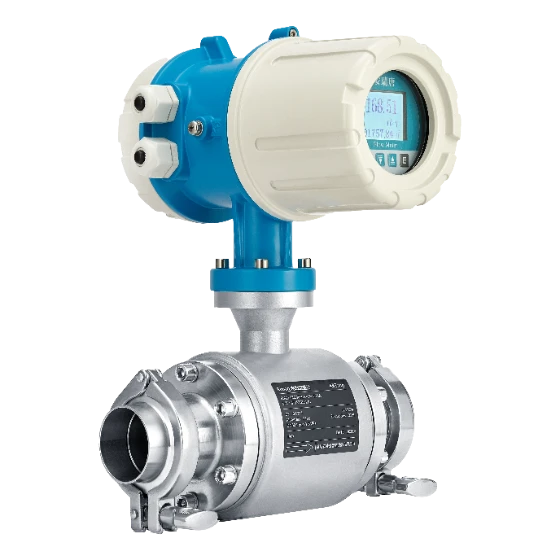

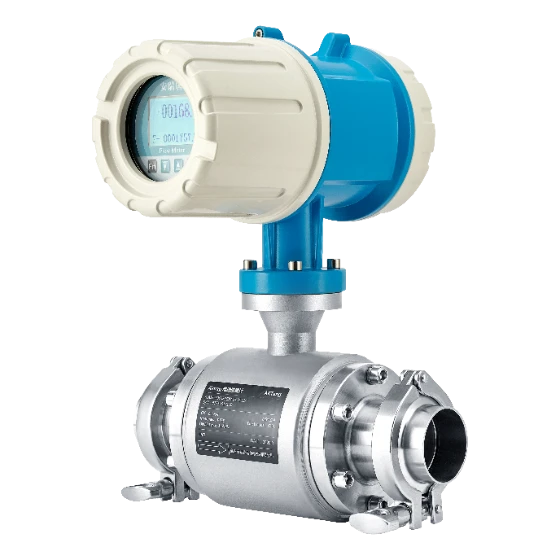

- Diameter nominal:DN6-DN150

- Accuracy:±0.5%/±0.2%

- Liner& Process Temperature:PFA: -40℃~160℃; PTFE: -40℃~130℃

- Process pressure:max. 40 bar

- Hygienic connection:Tri-clamp, Clamp, Thread, Welding

-

Hygienic DesignAll wetted parts are made from 316L stainless steel with food-grade liners PFA, compliant with FDA, 3A standards for sanitary applications.

-

Easy to Clean (CIP/SIP Ready)Smooth, seamless flow path prevents residue buildup. Fully compatible with CIP and SIP systems to avoid cross-contamination.

-

High Accuracy and StabilityDelivers precise measurements with accuracy up to ±0.2%–±0.5%, even for viscous or slightly particulate liquids.

-

No Moving Parts, Maintenance-FreeBased on electromagnetic measurement principles—no wear, no clogging, ensuring long-term stable performance with minimal maintenance.

-

Multiple OutputsSupports 4–20mA, pulse, RS485, and HART for flexible integration with control systems.

-

Fast ResponseRapid signal processing enables real-time flow tracking, ideal for batch control, dosing, and continuous flow monitoring.

One of the main advantages of sanitary electromagnetic flowmeters is that they can accurately measure regardless of the type of medium being measured, as well as its temperature, viscosity, and density, making them ideal for food processing applications.

The design of sanitary electromagnetic flowmeters meets food grade standards, and the suppliers of linings are the same as E+H and Krohne. The smooth, seamless design makes cleaning easier and less likely to breed bacteria, which better ensures a hygienic food environment.

The plastic parts of sanitary electromagnetic flowmeters are all FDA certified. Food hygiene requires a minimum metal material of stainless steel 304. We use stainless steel 316L with better hygiene requirements. It is a perfect choice for food and beverage processing plants.

Model | Aimag H |

Applications | Food/Pharmaceutical |

Nominal Diameter | DN6~DN150 |

Electrode | Stainless steel, Hastelloy. Titanium, Tantalum, Platinum |

Liner&Process Temperature | PFA:-20~150℃(Compact) |

PFA:-20~180℃(Remote) | |

Process Connection | Clamp,Welding,Flange |

Process Pressure | PN16~40 CI.150/300 JIS 10K/20K |

Accuracy | ±0.5%/0.2% |

Output | 4~20mA/Frequency/Pulse |

Communication | HART, Modbus RS485,PROFIBUS DP |

Certificates | CE,SIL,CNEX,NEPSI,3-A |

Protection Grade | IP67(IP68 optional) |

Advantages Of Sanitary Electromagnetic Flow Meters

1. The Only One Manufacturer Who Obtained 3-A Sanitary Standards Certificate for Flow Meters in China;

2. High temperature resistance, acid, alkali, complywith CIP/SIP cleaning and sterilization requirements;

3. High Temperature Resistance, Food grade liner with stands high temperature steam disinfection:Integral type: -40°~ 135°C Separate type: -40°~ 180°C;

4. Food hygiene requires a minimum metal material of stainless steel 304. We use stainless steel 316L, which has better hygiene requirements;

5. The supplier of the lining is the same as E+H and Cologne, and the process connections are formed in one piece to ensure that the roughness meets the requirements, the strength is higher, and it is more hygienic and safer;

6. All relevant wetted plastic parts have passed FDA certification. All relevant wetted metal parts are tested using spectrometers and have material certificates;

7. Ensure that the proportion and content of elements meet food requirements. The smaller the surface roughness, the better the surface finish of the product, the less likely it is for residues to adhere, and the easier and cleaner it is to clean. Not easy to breed bacteria, better ensuring food hygiene environment;

8. Process connection: The wetted part is made of 316Lstainless steel to meet hygienic requirements,and meet the requirements of polishing degree.