- Measure range:5~50m(optional)

- Blind zone:0.3m

- Accuracy:±0.5%FS, ±1%FS

- Power supply:220VAC, 50Hz; 24VDC, 120mA

-

Non-contact measurementNon-contact continuous measurement, reducing maintenance

-

High Adaptability:Suitable for level monitoring in tanks, vessels, and pipelines, covering a wide range of applications.

-

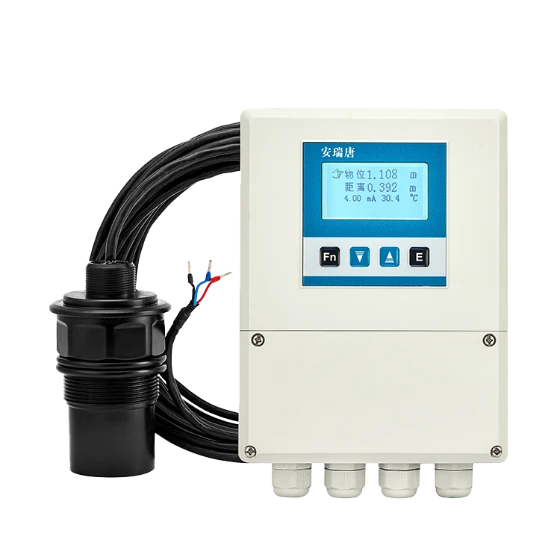

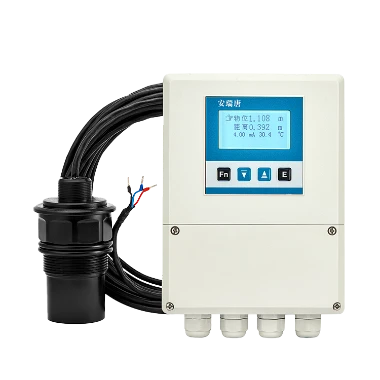

Strong Interference Resistance:With the probe and processor separated, the signal unit can be installed away from areas with high temperature, pressure, or electromagnetic interference.

-

Easy to Operate:Larger display and more interfaces make adjustments and monitoring simpler.

-

Highly Adaptable:Split design works well in high-temperature or corrosive environments.

-

Remote Monitoring:Can be integrated with remote systems to transmit data over the network for remote monitoring and management.

The ultrasonic liquid level sensor measures the time it takes for an ultrasonic pulse to travel through the entire process from emission to return. The ultrasonic liquid level sensor is installed vertically on the surface of liquid, it sends out an ultrasonic pulse to the liquid surface, after a period of time, the sensor of the ultrasonic liquid level sensor receives the signal reflected back from the liquid surface, the signal is selected and processed by the transmitter circuit, and according to the difference of the time between the ultrasonic level sensor sends out and receives ultrasonic waves, it calculates the distance from the liquid surface to the sensor. ultrasonic liquid The ultrasonic liquid level sensor is widely used for liquid level and volume measurement in tanks, pools and reservoirs, and also for flow measurement in open channels.

Functions | Integrative Type | Segregated Type |

Level Range | 5m, 8m, 10m, 15m, 20m, 30m, 50m | 5m, 8m, 10m, 15m, 20m, 30m, 50m |

Accuracy | 0.5%-1%F.S | 0.5%-1%F.S |

Blind Zone | 0.3-1.8m | 0.3-1.8m |

Working Pressure | 2 Bar (Explore Proof Type is 5 Bar) | 2 Bar (Explore Proof Type is 5 Bar) |

Resolution | 3mm or 0.1%F.S (Max of them) | 3mm or 0.1%F.S (Max of them) |

Analog Output | 4~20mA/510Ω load resistance (4 wire) | 4~20mA/510Ω load resistance (4 wire) |

4~20mA/250Ω load resistance (2 wire) | 4~20mA/250Ω load resistance (2 wire) | |

Relay/Alarm Output | AC 250V/ 8A; | AC 250V/ 8A; |

DC 30V/ 5A; | DC 30V/ 5A; | |

State programmable (optional for 4 wire) | State programmable (optional) | |

Power Supply | 24VDC | 220VAC, 50Hz |

220VAC, 50Hz | 24VDC, 120mA | |

Environment Temperature | Meter : -20~+60°C | Meter -20~+60°C |

Sensor: -20~+80°C | Sensor -20~+80°C | |

Communication | RS485 Communications (optional) | RS485 Communications (optional) |

Explore Proof | Ex(ia)CT6 | Ex(ia)CT6 |

Water Proof | Probe: IP68 ; sensor: IP66 | Probe: IP68; sensor: IP65 |

Store Request | Temperature: -20~+80°C | Temperature -20~+80°C |

Pressure atmospheric pressure | Pressure:atmospheric pressure | |

Humidity≤90%RH | Humidity ≤90%RH | |

Others Non-corrosive gases (optional corrosion probe) or steam, no vibration. | Others Non-corrosive gases (optional corrosion probe) or steam, no vibration. |

Product features of ultrasonic liquid level sensor:

1. Fearless of corrosive gases: In the environment of corrosive gases, you can choose PTFE anti-corrosion probe.

2. Small blind zone measurement: The blind zone measurement is fully optimized to reduce the blind zone of the product.

One-piece: 5m liquid ≤ 0.4m; 10m liquid ≤ 0.4m; 15m liquid ≤ 0.5m

Split: 5m liquid ≤ 0.3m; 10m liquid ≤ 0.35m; 15m liquid ≤ 0.5m

3. ± 0.5% high accuracy: automatic temperature compensation, effective protection of the display instrument IP65 protection, IP68 protection of the sensor. IP68 protection. 4.

4. with RS485/232 serial data output or 4-20mA/0-20mA analog output or 1-5V/0-5V analog output (optional). 5. with temperature compensation, window locking.

5. with temperature compensation, window locking and anti-interference error correction function, the medium speed adjustment and other functions (optional when ordering).