Printing and dyeing industry belongs to the three high industries of high energy consumption, high water consumption and high pollution. Electromagnetic flowmeter in paper industry is used for pulp flow, paint and ink placement, cooling water flow, wastewater treatment monitoring and energy management. Ensure quality, stabilize production, save energy and reduce emissions, improve production efficiency and environmental sustainability.

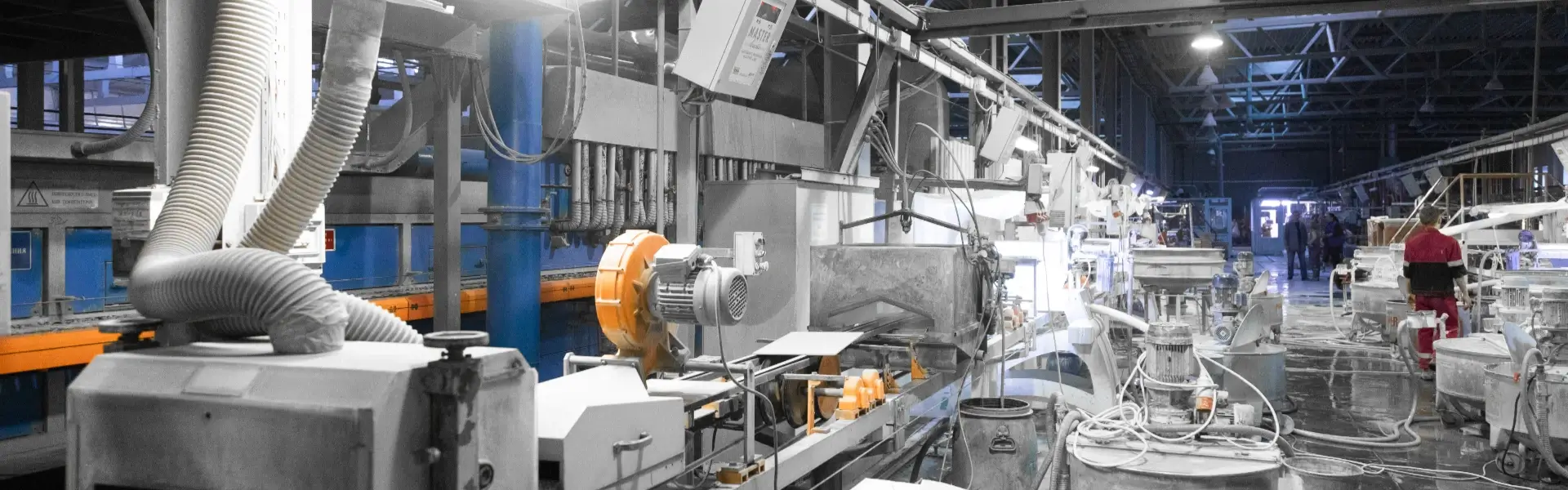

ARTang instrumentation products are currently used in many parts of the printing and dyeing industry, and their stable and reliable performance can help you effectively improve on-site processing efficiency and save production costs.

1、Preparation process

The main task of the preparation section is to make slurry from different raw materials. ARTang magnetic flow meter is mainly involved in the flow measurement of polished slurry, water and acid or alkali in the slurry making process. Generally the temperature of the slurry has to reach 80°C after mechanical grinding. When the wood or grass and other materials as raw materials for pulping often have to go through the cooking process. As the cooking solution for alkali such as Ca (OH) 2 or Na0H solution, the slurry are alkaline, so the electromagnetic flowmeter is mostly used in high-temperature-resistant polytetrafluoroethylene lining and split-type structure type. In the choice of electrode materials to consider the selection of corrosion-resistant materials. Alkaline slurry is generally used Hastelloy Hc, titanium Ti and other materials, do not choose tantalum electrode; and if the measurement of acidic slurry, the requirements are not high, you can also choose acid-resistant steel 316SS.

Many enterprises use waste paper pulp, that is, waste paper pulping and then washing and bleaching treatment, here magnetic flow meter is mainly used to measure the flow of water involved in pulping. Most of the water for the nearby river water slightly processed to participate in the operation, so the water quality is poor, but no corrosive, magnetic flow meter with conventional rubber lining and stainless steel electrodes can be used; and to participate in the deinking process of deinking agent (common deinking agent Na0H, Na2SiO3, Na2O2 or H2O2) measurement, electromagnetic flowmeter electrodes and lining selection should be careful.

2. Screening and bleaching section

Electromagnetic flowmeter used in the preparation workshop from each into the paper shop pulp pool of the inflow and outflow from each pool of pulp pool flow measurement points, a total of five kinds of pulp (chemical pulp, deinking pulp, CTMP, machine pulp, loss of liquid pulp) involved in the process of pulp distribution. Here machine pulp and CTMP pulp temperature up to 50-80 ℃, flowmeter lining materials should be considered to choose PTEE.

magnetic flow meter in the field of papermaking is commonly used PTFE or other fluorine plastic lining: electrode according to the nature of different liquids are selected.