Pulp and paper production of a large number of liquids used in the conductivity are greater than 20 uS/cm, this situation meets the basic measurement requirements of electromagnetic flowmeter. Electromagnetic flowmeter does not make the nominal diameter of the pipe reduced or may be blocked by the fiber parts, this feature in the measurement of pulp flow is extremely important. Therefore, in recent years, the use of electromagnetic flowmeter to measure the pulp flow method has been widely used.

Problems faced by the measurement

(1) High temperature and high pressure

Generally, the temperature of the slurry after mechanical pulping is up to 80℃ or more. The black liquor extraction and recycling process is also a high temperature and high pressure environment.

(2) liner wear

high concentration of pulp, waste paper liquid, cooking spray line will produce serious wear and tear on the electromagnetic flowmeter liner.

(3) pulp noise interference

high concentration of pulp, fiber in the flow through the electromagnetic flowmeter is easy to electromagnetic flowmeter electrode friction, resulting in spike noise interference.

(4) electrode scaling

In the measurement of fuels, chemicals, easy to product liquid, electromagnetic flowmeter electrodes will be covered with insulating adherents, thus affecting the measurement.

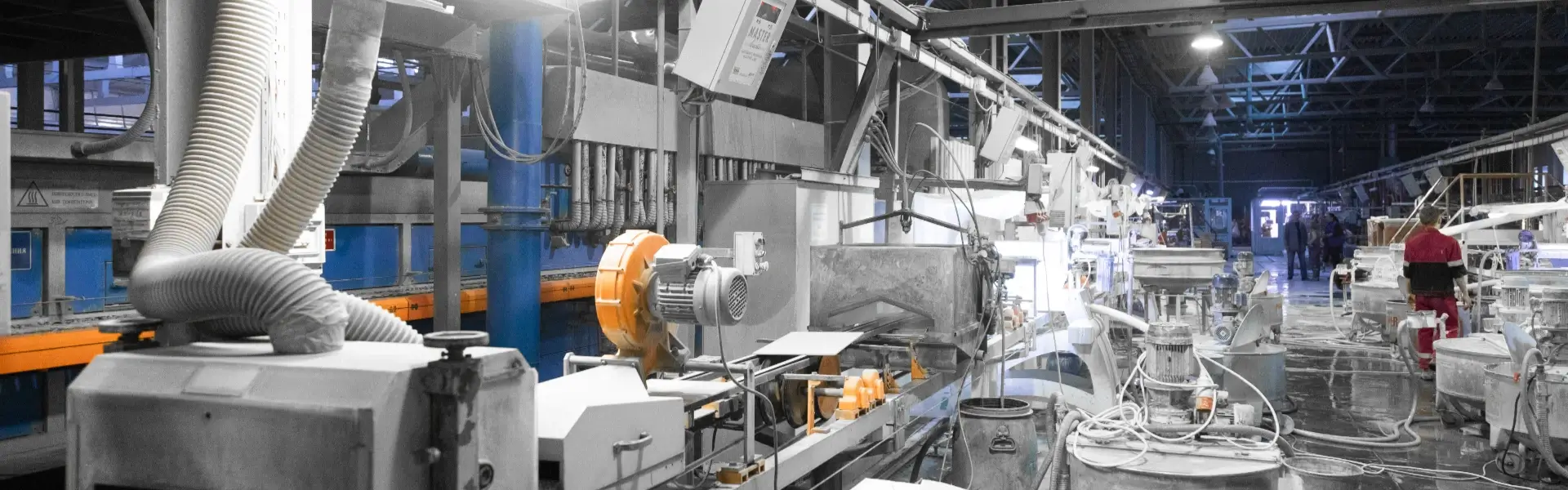

Electromagnetic Flow Measurement

Flow Meter Wastewater Treatment

In the papermaking line, the medium that needs flow measurement is mainly divided into pulp (pulp, bamboo pulp) and black liquor. A famous paper mill in Guangxi contacted our company in 2022, hoping to provide solutions for the measurement of their company's black liquor. The company's black liquor mainly includes two process sections: one is the evaporation process section of the black liquor, media temperature 120 ℃, media concentration <3%; the second is the cooking process section of the black liquor, media temperature 170 ℃, media concentration <3%. Users require stable and accurate flow measurement, and the level meter quantity match, the measured value display fluctuation <2%, and the service life. For the evaporation process section of the black liquid.

RTang Aimag A Electromagnetic Flow Meter, split type, PTFE lining, 316L stainless steel electrode. For the black liquor in the cooking process section, for its high temperature characteristics, RTang customized the thickened PTFE lining, and the excitation coil inside the sensor as well as the magnetic circuit system to do thermal insulation, heat dissipation treatment; electrode, using spherical 316L electrode, in order to prevent thermal expansion of the lining caused by the electrode insulation is not good, the use of a special electrode locking structure. Users listen to my company's program immediately after the purchase of 25 units, split electromagnetic flowmeter, the current operating time has been more than 3 years.