In the chemical industry, the stability of the production process, high efficiency and accurate control of product quality, cost and safety, chemical electromagnetic flowmeter flow monitoring is a key link, such as polymerization reaction, esterification reaction, etc., often need to be carried out at high temperature and high pressure conditions, and the reaction process involves raw materials and products are mostly conductive liquid. Electromagnetic flowmeter can be installed in the raw material transportation pipeline, accurate measurement of the flow of various raw materials into the reactor, to ensure that the pre-determined ratio of feed, so that the chemical reaction can be carried out smoothly, to ensure product quality and yield. For example, in the PTA (fine terephthalic acid) production, PTA refining section of crude terephthalic acid (CTA) slurry booster pump to go to the fifth crystallizer preheater pipeline, it is necessary to use electromagnetic flowmeter to measure the flow of CTA slurry, because of the CTA slurry in the pipeline, high temperature, fast flow rate, flow rate, the flow rate of the accurate measurement of the product quality is critical to judge.

Flow monitoring in chemical industry

Chemical production involves complex chemical reactions and material transportation, flow as a core process parameter, which directly affects:

1, material proportioning accuracy: such as PTA production, each link of raw materials, additives, flow control, to determine whether the reaction is carried out in accordance with the optimal ratio, which is related to the yield and quality of the product.

2, energy cost control: accurate flow monitoring can avoid waste caused by excessive material delivery, optimize energy distribution, reduce production costs.

3, safety risk prevention and control: abnormal fluctuations in flow rate may indicate pipeline blockage, equipment failure, timely monitoring can be early warning, effective prevention and control.

ARTang chemical electromagnetic flowmeter used in PTA refining section, for example, crude terephthalic acid (CTA) slurry flow control, directly affecting the subsequent hydrogenation and refining, crystallization and separation of the effect is to ensure that the PTA purity of the basis of the standard.

PTA refining section: accurate application of ARTang electromagnetic flowmeter

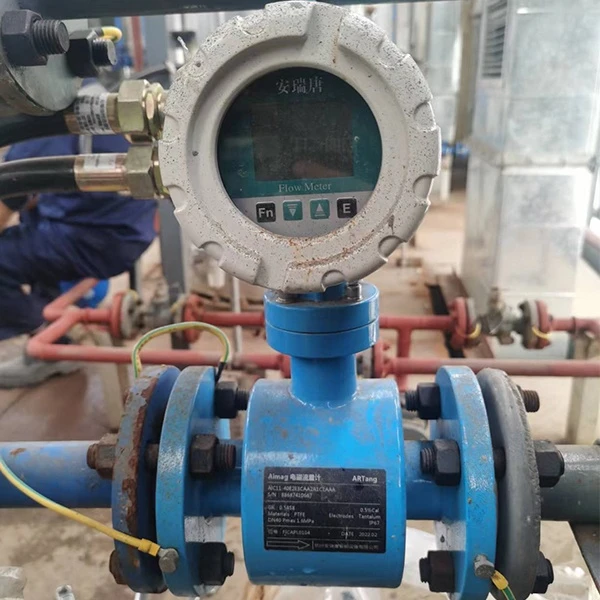

In the refining section of PTA production of XXXX Co., Ltd, ARTang chemical electromagnetic flowmeter is deeply adapted to the complex process:

1. Process Scenario and Program Design

In the refining section, CTA slurry is transported to the fifth crystallizer preheater by booster pump. The pressure in the pipeline is high (e.g. several MPa in some parts of the pipeline), and the medium (CTA slurry) has high temperature and fast flow rate. Ordinary electromagnetic flowmeter is not enough to withstand the pressure, thus, the company used ARTang C electromagnetic flowmeter, which takes into account the cost and measurement accuracy.

Advantages of chemical electromagnetic flowmeter

1, high-pressure environment adaptation: CTA slurry in the section after pressurization of high pressure, Anritsu Tang high-pressure electromagnetic flowmeter, the use of high-strength shell and sealing process, high pressure impact resistance, to ensure long-term stable operation, to eliminate the risk of media leakage.

2, accurate measurement guarantee: CTA slurry containing solid particles, high temperature, flowmeter optimization of the magnetic circuit and electrode design, with corrosion and wear-resistant lining (such as PTFE), accurately capture the flow signal, even in the complex flow state, the measurement error is still controlled in a very small range for the hydrogenation reaction ratio, crystallization and separation process, to provide reliable data.

Advantages of chemical electromagnetic flowmeter

l Product quality upgrade

Accurate flow monitoring to ensure the stability of CTA slurry delivery, hydrogenation and refining link material ratio is accurate, effectively reduce the 4-CBA and other impurities residue, PTA product purity enhancement, help downstream polyester production quality upgrade.

l Cost optimization and control

flowmeter durability, low frequency of operation and maintenance, save the later maintenance costs; accurate flow control to avoid material waste, optimize energy consumption, long-term operation can significantly reduce production costs; early warning flow abnormalities, reduce equipment failure and downtime losses.

l Production efficiency improvement

flowmeter is stable and reliable, guaranteeing continuous operation of refining section; real-time accurate data support dynamic adjustment of process parameters, shorten the production debugging cycle, and help release production capacity.

CTA slurry is high-pressure, particle-containing and corrosive, which is a great test for instrument structure and material. Arraytang adopts high-strength stainless steel shell + customized corrosion and wear-resistant liner and electrode for the working conditions, and passes strict tests to ensure long-term stable operation.

In the refining section of chemical PTA production, ARTang chemical electromagnetic flowmeter has become an important guarantee for the stable operation of the process with “accurate measurement, reliable adaptation and cost optimization”. From the necessity of flow monitoring, to the in-depth application of complex scenarios, to the breakthroughs in customer benefits and challenges, ARTang uses its technology and services to help chemical enterprises cope with the financial pressure and production uncertainty, and to make the “precise control, cost reduction and efficiency enhancement” from a goal to a reality.