-

Date:2025-11-06

-

Page View:194

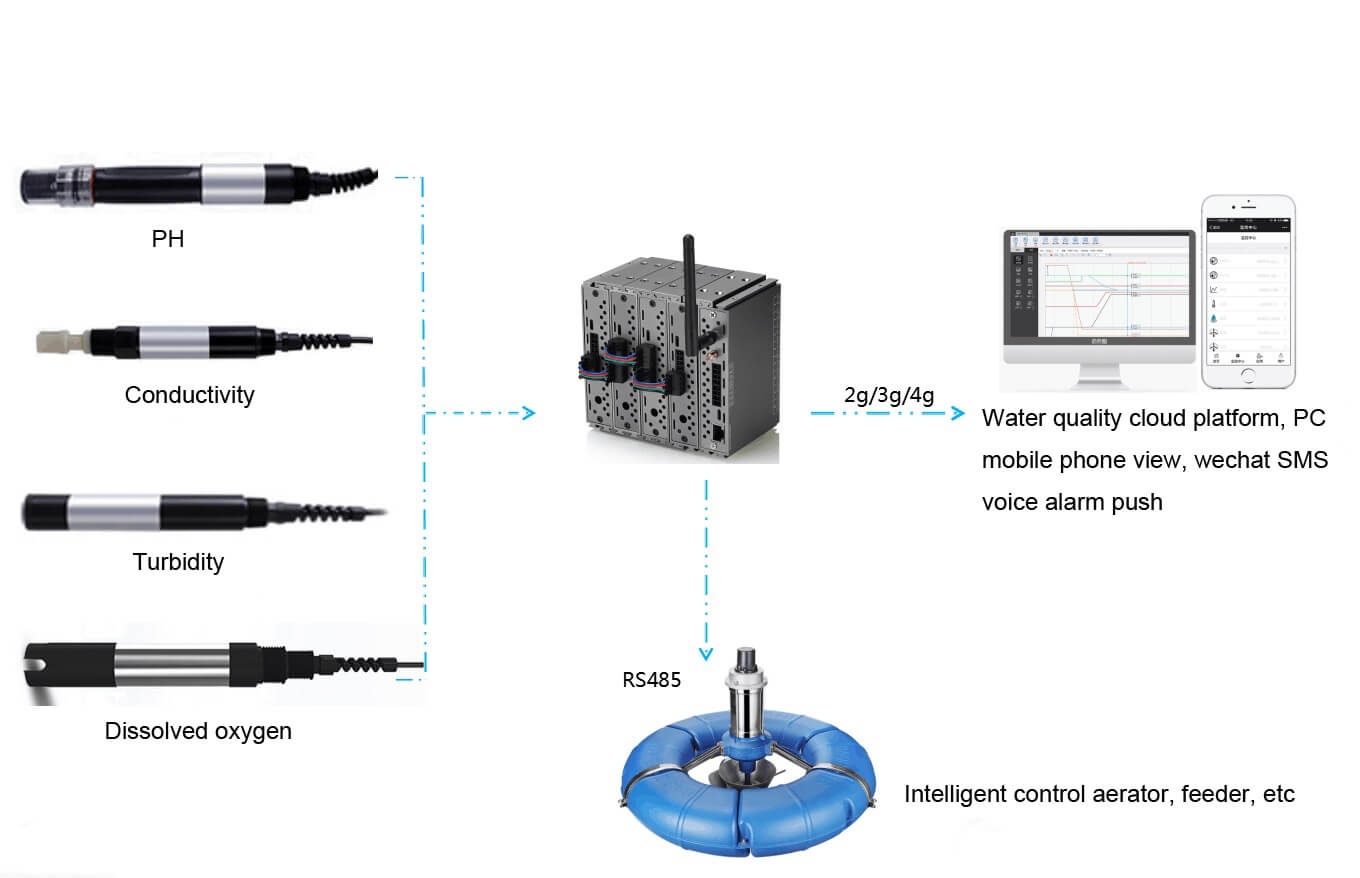

Common water-quality sensors used in aquaculture include pH sensors, dissolved oxygen sensors, temperature sensors, conductivity sensors, turbidity sensors, and ammonia-nitrogen sensors. Water quality directly affects the growth and overall condition of aquatic products. To ensure stable and suitable water conditions, multiple water-quality sensors are required to continuously monitor various parameters in real time. These sensors provide accurate, up-to-date data, helping farmers better manage the aquaculture environment and improve both the growth rate and quality of their products.

Common Water-Quality Issues in Fish Farms

Fish farms often face multiple water-quality challenges at the same time. Dissolved oxygen causes the most serious problems—low oxygen levels result in more fish deaths than all other water-quality issues combined.

Excess ammonia from fish waste and uneaten feed can create a toxic environment. This slows fish growth and damages their gills.

pH levels outside the optimal range (typically 6.5–8.5) can severely affect fish reproduction and growth. During breeding seasons, fish become especially sensitive. Fish eggs and fry are far less tolerant of harsh conditions than adult fish.

Overcrowded or poorly managed aquaculture systems often accumulate large amounts of waste. Producing one kilogram of fish generates roughly one kilogram of waste, which contains up to 70% nitrogen. This leads to a dangerous cycle: ammonia increases, while oxygen levels decrease.

Aquaculture Sensors and Their Measurement Functions

Specialized sensors that continuously track water parameters are essential for successful aquaculture monitoring. These devices help manage water quality and measure specific indicators that directly affect fish health.

Dissolved Oxygen (DO) Sensors

Dissolved oxygen (DO) is the most critical water-quality parameter in fish farming. DO levels can shift from safe to lethal within hours—or even minutes—making it a parameter that must be monitored closely.

Modern systems primarily use two types of DO sensors:

Electrochemical sensors (galvanic or polarographic)

Optical DO sensors

Optical sensors require no warm-up time and no water flow to operate, making them ideal for fixed monitoring points.

pH and ORP Sensors

Most aquatic species thrive when the pH is maintained between 6.5 and 8.5. pH sensors typically use a single-junction, three-electrode design with a refillable reference solution to ensure accurate measurements.

ORP (Oxidation-Reduction Potential) sensors help track the water’s ability to oxidize or reduce substances. These readings provide insight into overall water health and can detect harmful compounds early.

When used together, pH and ORP sensors provide early warnings of water-quality issues before they become severe.

Temperature and Turbidity Sensors

Fish health depends heavily on water temperature, which affects their metabolism as well as oxygen levels in the water. High-quality temperature sensors typically operate between –5°C and 35°C and can detect changes as small as 0.01°C.

Water clarity is measured using turbidity sensors, which detect suspended particles. These particles block light and reduce oxygen exchange. When turbidity becomes too high, water temperature rises and fish feeding behavior can change.

Ammonia and Nitrate Sensors

Ammonia is one of the most dangerous compounds in aquaculture. It comes from decomposing organic matter, fish waste, and uneaten feed. Nitrate sensors track another key nitrogen compound; high readings often indicate that the system is out of balance. These sensors help detect dangerous conditions early and prevent fish mortality.

Conductivity and Salinity Sensors

Water conductivity and salinity must be continuously monitored. These sensors use inductive (toroidal) coil technology or a four-electrode measurement system, both of which operate reliably even under harsh conditions.

Salinity is critical for many aquatic species, and careful monitoring is especially important in seawater and brackish-water applications.

Calibration Methods for Aquaculture Equipment Sensors

Calibrating sensors is essential for ensuring measurement accuracy and reliability. Below are common calibration methods for various aquaculture monitoring sensors:

Temperature Sensor Calibration

Steps:

1. Use a calibrated reference thermometer and compare it with the sensor in water of a known temperature (such as an ice–water mixture or boiling water).

2. Place both the sensor and the reference thermometer in the same water bath, record the readings, and adjust the sensor output based on any differences.

Dissolved Oxygen (DO) Sensor Calibration

Steps:

1. Zero calibration: Place the sensor in an oxygen-free environment (such as a sodium sulfite solution or chemical deoxygenation setup) and adjust it to zero.

2. Slope calibration: Place the sensor in water with a known oxygen concentration (typically using a standard DO solution) and adjust it to match the correct value.

pH Sensor Calibration

Steps:

1. Use two standard buffer solutions—typically pH 4.01 and pH 7.01, or pH 7.01 and pH 10.01—for calibration.

2. Immerse the sensor in each buffer solution sequentially and adjust the readings to match the known pH values.

Conductivity Sensor Calibration

Steps:

1. Calibrate using a standard solution with a known conductivity value.

2. Immerse the sensor in the standard solution and adjust it until the correct conductivity reading is displayed.

Ammonia Nitrogen (NH₃–N) Sensor Calibration

Steps:

1. Use a standard solution with a known ammonia-nitrogen concentration.

2. Immerse the sensor in the standard solution and adjust the reading to match the known concentration.

Nitrite Sensor Calibration

Steps:

1. Similar to the ammonia-nitrogen sensor, use a standard solution with a known nitrite concentration.

2. Immerse the sensor in the solution and adjust the reading as needed.

Turbidity Sensor Calibration

Steps:

1. Use a standard turbidity solution or a turbidity reference plate for calibration.

2. Align the sensor with the standard sample and adjust it to display the correct turbidity value.

Water Level Sensor Calibration

Steps:

1. Use a measuring ruler or cylinder with a known water height.

2. Compare the sensor reading with the scale or measuring cylinder and adjust it to show the correct water level.

Flow Sensor Calibration

Steps:

1. Use a standard flow meter (such as an electromagnetic or volumetric flow meter) as a reference.

2. Connect the sensor to the standard flow meter and calibrate it by comparing the flow readings.