-

Date:2025-11-04

-

Page View:214

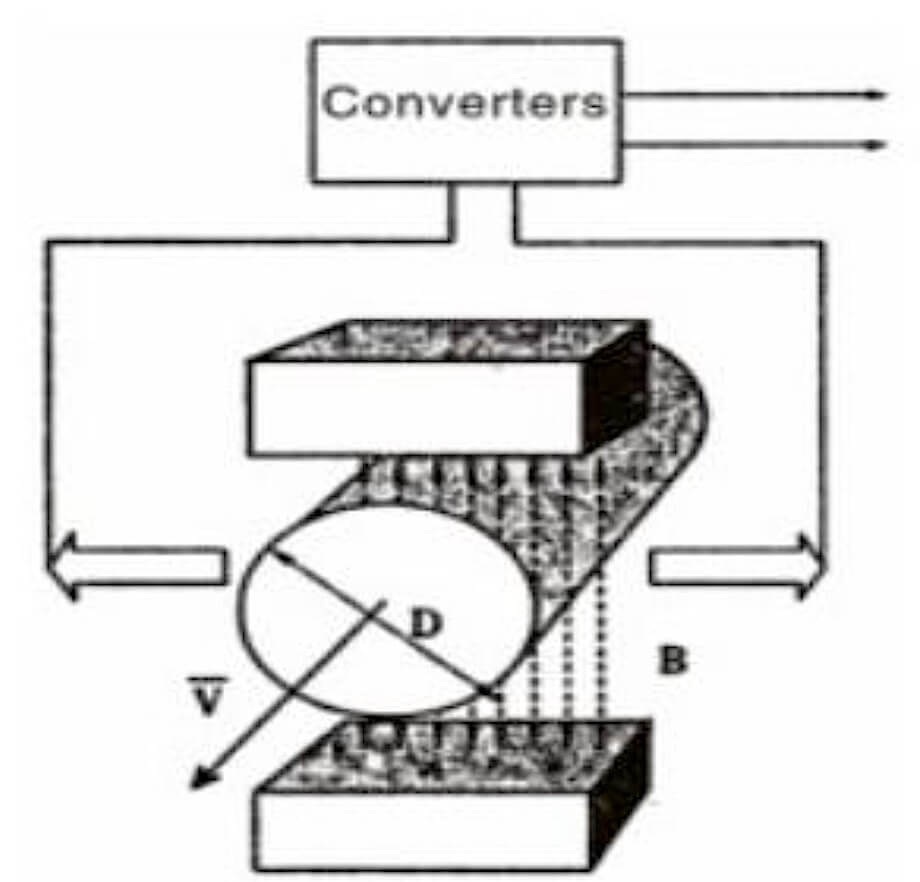

An electromagnetic flow meter operates based on Faraday’s law of electromagnetic induction. Its main structure consists of a magnetic circuit system, measuring tube, electrodes, housing, liner, and converter. This type of flow meter is very common in the market and is widely used in factories and chemical plants.

Working Principle of Electromagnetic Flow Meters

The operating principle of an electromagnetic flow meter is Faraday’s law of electromagnetic induction. It consists of a flow tube in which a magnetic field is applied perpendicular to the direction of the fluid flow. When a conductive fluid passes through the tube, a voltage proportional to the fluid’s velocity is generated. This voltage is detected by electrodes mounted on the tube wall, and the flow velocity can be calculated based on the induced voltage.

Advantages of Electromagnetic Flow Meters

No Moving Parts:

Low Maintenance: The absence of moving parts reduces wear and tear, resulting in lower maintenance costs and longer lifespan.

No Mechanical Failures: Less prone to mechanical issues compared to mechanical flow meters.

High Accuracy:

Precise Measurements: Typically offers high accuracy, often within ±0.5% of the measured value.

Wide Turndown Ratio: Can measure a wide range of flow rates with consistent accuracy, with a wide rangeability (1:100).

Works in Large Pipe Sizes

Available in sizes from DN6 to DN2200, making them suitable for both small and large pipelines.

No Obstruction to Flow:

Full-Bore Design: The flow path is unobstructed, minimizing pressure drop and preventing clogging.

Ideal for Slurries and Viscous Fluids: No risk of blockage or buildup in the flow path.

Minimal Sensitivity to Fluid Properties:

Unaffected by Density, Viscosity, or Temperature: Measures flow rate independently of these properties, as long as the fluid is conductive.

Compatibility with Hygienic Applications:

Sanitary Designs: Available in sanitary configurations for use in food, beverage, and pharmaceutical industries.

CIP/SIP Compatibility: Can withstand cleaning-in-place (CIP) and sterilizing-in-place (SIP) processes.

Suitable for Conductive Liquids:

Wide Range of Applications: Ideal for measuring the flow of conductive liquids, including water, slurries, acids, and bases.

Handles Abrasive and Corrosive Fluids: Can measure fluids with suspended solids or corrosive properties without damage to the meter.

Disadvantages of Electromagnetic Flow Meters

Limited application range:

Electromagnetic flow meters can only measure the flow of conductive liquids and cannot measure non-conductive media, such as gases or deionized water used in heating systems and water treatment equipment. In addition, the liner material must be carefully selected for its load-bearing capacity under high-temperature conditions and requires regular maintenance.

Dependence on fluid conductivity and density:

Electromagnetic flow meters determine the volumetric flow rate by measuring the velocity of conductive liquids. However, in some applications, mass flow rate is required. To obtain accurate mass flow measurements, the density of the fluid must also be considered.

Measurement errors with viscous or dirty fluids:

When measuring viscous or contaminated liquids, substances or sediments may adhere to the inner wall of the measuring tube or electrodes. This can cause changes in the transmitter’s output potential, leading to measurement errors. If the buildup on the electrodes becomes too thick, it can even cause the instrument to fail to measure properly.

Impact of pipeline scaling or wear:

Scaling inside water pipes reduces the internal diameter, while pipe wear increases it. Both conditions affect the original flow calibration and cause measurement deviations. For example, even a 1 mm change in a 100 mm inner diameter can result in an additional error of about 2%, ultimately reducing overall measurement accuracy.

Electromagnetic Flow Meters

Insertion Type Magnetic Flow Meter

Factors to Consider When Choosing an Electromagnetic Flow Meter

Fluid properties: Consider the fluid’s conductivity, viscosity, and temperature to ensure compatibility with the chosen flow meter.

Pipe size and flow range: Determine the pipe diameter and the expected flow range to select a flow meter capable of accurately measuring the required flow rate.

Installation requirements: Evaluate the available installation space and any requirements for straight pipe runs or flow conditioning elements.

Output and integration: Assess the output signal types needed and ensure compatibility with existing control systems or data acquisition equipment.

Common Misconceptions About Electromagnetic Flow Meters

Limited suitability for clean fluids:

Although electromagnetic flow meters are often used in dirty or contaminated fluid applications, they can also accurately measure clean fluids. They are capable of handling a wide range of fluid types and are suitable for diverse applications.

Sensitivity to air bubbles:

Some users believe that air bubbles can affect the accuracy of electromagnetic flow meters. However, modern models are equipped with bubble detection and compensation algorithms that minimize the impact of air bubbles on measurement accuracy.

Low accuracy with slurry measurement:

Electromagnetic flow meters can accurately measure slurries with high solid content, as long as the solids are electrically conductive. The measurement accuracy may be influenced by factors such as solid concentration and particle size distribution, but with proper setup, reliable results can still be achieved.

Comparison with Other Types of Flow Meters

Accuracy:

Even when measuring fluids with varying conductivity, electromagnetic flow meters provide high measurement accuracy, outperforming other types such as turbine or paddlewheel flow meters.

Versatility:

Unlike some flow meters that have limitations in fluid compatibility, electromagnetic flow meters can handle conductive fluids with different viscosities and corrosive properties, making them suitable for a wide range of applications.

Maintenance:

Since electromagnetic flow meters have no moving parts, they require minimal maintenance and offer long-term reliability.

Electromagnetic flow meters offer numerous advantages in terms of accuracy, versatility, and low maintenance requirements. They are highly suitable for measuring the flow of conductive fluids across a wide range of industries. However, their limitations—such as the inability to measure non-conductive fluids and reduced accuracy at very low flow rates—should be taken into account. Regular maintenance and calibration are essential to ensure accurate and reliable performance throughout the meter’s service life.