-

Date:2025-10-16

-

Page View:206

The Sanitary Electromagnetic Flow Meter is a specialized flow measurement instrument designed for industries such as food, pharmaceuticals, and beverages. It is used for metering, batching, and controlling finished product filling.

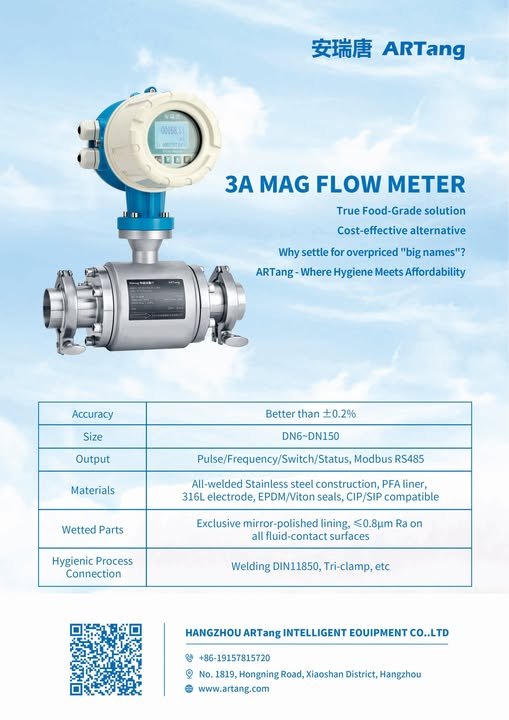

The ARTang Aimag H Sanitary Flow Meter features a 316L stainless steel body, sanitary clamp connections, and complies with 3A standards. Regarding our FDA-certified sanitary flow meters, the PFA lining material must also meet FDA certification requirements. These meters are widely used in the food and beverage industry.

Sanitary Flow Meters: Application Advantages

High-Precision Measurement: Utilizing advanced electromagnetic induction technology, the Aimag H sanitary flow meters deliver highly accurate flow measurement. This ensures precise control throughout the food and beverage production process.

Wide Measurement Range: This series of electromagnetic flowometers offers an extensive measurement range, capable of meeting the flow measurement requirements of various food and beverage processing equipment under diverse operating conditions.

Hygienic Design: Engineered to meet the specific demands of the food and beverage industry, the Aimag H flow meters feature a 316L stainless steel sensor housing. All wetted parts are cleanable via CIP (Clean-in-Place) and SIP (Steam-in-Place) processes.

They are equipped with sanitary clamp connections and a PFA liner that is FDA-approved. As the only manufacturer in China with 3A food certification for this product, our design strictly complies with all hygiene and safety regul

Reliability and Stability: This series of sanitary flow meters is built for high reliability and stability, ensuring long-term, consistent operation in the continuous, demanding environments typical of food and beverage plants.

Excellent Compatibility: The Aimag H sanitary electromagnetic flow meters integrate seamlessly with a wide variety of food and beverage processing equipment, enabling smooth connection within the production line.

Core Advantages of Sanitary Flow Meters

High Hygiene Standards: Featuring polished surfaces (Ra ≤ 0.8µm), they comply with international sanitary certifications such as 3A and EHEDG, making them suitable for aseptic environments.

Accuracy and Stability: Unaffected by fluid density or viscosity, these meters achieve a measurement accuracy of up to ±0.5%, ideal for high-precision ratio control.

Easy Maintenance: With no moving mechanical parts, they are virtually maintenance-free, have a long service life, and help reduce operating costs.

Smart Integration: Supporting communication protocols like 4-20mA, HART, and Modbus, they can be seamlessly integrated into DCS/PLC systems for intelligent process management.

Application Scenarios of Sanitary Flow Meters

A sanitary flow meter is a specialized flow measurement instrument designed for applications with stringent hygiene requirements. Its structure and materials must meet criteria such as easy cleaning, corrosion resistance, and dead-leg-free design to prevent media residue and bacterial growth. Below are common application scenarios and their corresponding features:

1. Food & Beverage Industry

Application Scenarios: Dairy processing (e.g., milk, yogurt production), beverage filling (juices, carbonated drinks), baked goods manufacturing, edible oil production, and more.

Requirements: Equipment must come into contact with food media like milk and sauces, requiring smooth, non-porous surfaces to prevent contamination.

Sanitary electromagnetic flow meters are used to measure the flow of various liquid media. Constructed with 316L stainless steel or PTFE lining that meets food-grade standards, they prevent product contamination. Their obstruction-free design facilitates Clean-in-Place (CIP) and Steam-in-Place (SIP) processes, ensuring the hygiene and safety of the production line.

2. Pharmaceutical & Biotechnology Industry

Application Scenarios: Active Pharmaceutical Ingredient (API) production, drug formulation (injectables, oral medications), bioprocessing (vaccine, antibiotic production), and gas monitoring in cleanrooms.

Sanitary electromagnetic flow meters utilize aseptic connections (e.g., Tri-Clamp fittings) to prevent bacterial proliferation and meet GMP certification requirements. Compliance with Good Manufacturing Practice (GMP) standards is essential. Materials of construction, such as 316L stainless steel, must offer high corrosion resistance. Surfaces require polished finishes (with a roughness Ra ≤ 0.8 µm) to prevent drug substance retention.

3. Water Treatment & Purified Water Systems

Application Scenarios: Potable water treatment, purified water production (e.g., pharmaceutical-grade water, electronic-grade ultrapure water), and seawater desalination.

Requirements: These meters are used to monitor inlet and concentrate stream pressure in Reverse Osmosis (RO) membrane filtration stages to control filtration efficiency. When in contact with purified water, the materials must be non-toxic and non-leaching to prevent secondary contamination. They must also withstand sanitization methods such as ozone and UV treatment.

4. Dairy & Milk Processing

Application Scenarios: Cheese production, milk powder spray drying, pasteurization of fresh milk, etc.

Requirements: In pasteurization equipment, these meters monitor steam pressure to ensure precise sterilization temperatures (e.g., maintaining 72°C for 15 seconds). They provide accurate flow measurement for milk, cream, and other dairy products, delivering reliable data support for batching and filling processes.

With advantages such as their sanitary design, high-precision measurement, no-pressure-loss design, smart communication capabilities, and ease of installation and maintenance, food-grade electromagnetic flow meters play a vital role in the food processing, pharmaceutical, beverage, and dairy industries. As industrial automation continues to advance, these flow meters will keep providing reliable and accurate flow measurement solutions, driving ongoing progress and development within these sectors.