-

Date:2025-07-31

-

Page View:291

The Electromagnetic water flow meter is designed to measure a wide range of conductive liquids. Application areas include: water / sewage, pharmaceutical, chemical, paper, food and other industries. According to the classification of the diameter of the pipeline, large diameter magnetic inductive flow meter is mostly used in the field of water supply and drainage, small and medium diameter electromagnetic flow meter is mostly used for solid-liquid biphasic fluids and other difficult to measure the fluid or higher requirements of the occasion, the small diameter and small diameter of the electromagnetic water flow meter is mainly used in the Small diameter and small caliber electromagnetic water flow meter is mainly used in the pharmaceutical industry, food industry, bioengineering and other places that have strict requirements for hygiene.

How Does an Electromagnetic Water Flow Meter Work?

An electromagnetic water flow meter operates on the principle of electromagnetic induction. As the conductive fluid flows through the pipe, it cuts across the magnetic field created by the sensor. According to Faraday's law, this movement induces a voltage in the fluid, which is sensed by the electrodes. By measuring the induced voltage, the flow meter can determine the flow velocity and calculate the volumetric or mass flow rate.

The magnetic field strength, generated by the sensor, plays a crucial role in the accuracy of the measurement. The electrode arrangement ensures that the voltage is measured accurately across the fluid's cross-sectional area. Sophisticated algorithms and signal processing techniques further enhance the accuracy and stability of the measurements.

Classification of Electromagnetic Water Flow Meter

electromagnetic water flow meter is classified according to the excitation mode, there are DC, AC, rectangular wave excitation.

According to the assembly form for classification, there are split type and one body type. Currently more commonly used in the petrochemical industry is a body type, but when the site environment is more severe, such as underground, there are strong vibration of the pipeline, or the converter needs to be installed in the inspector more accessible occasions more need to split the type of magnetic inductive flow meter.

Classified according to the connection with the pipeline, there are flange type, insertion type, clamping type and so on. Flange connection is the traditional connection and also the most commonly used connection in the petrochemical industry. However, in some relatively thick pipeline, or the installation of harsh conditions, the insertion type flowmeter is smaller and more conducive to maintenance is more suitable.

According to whether the electrode and the measured liquid contact classification, there are contact and non-contact type. At present, the petrochemical industry commonly used or contact type electromagnetic water flow meter.

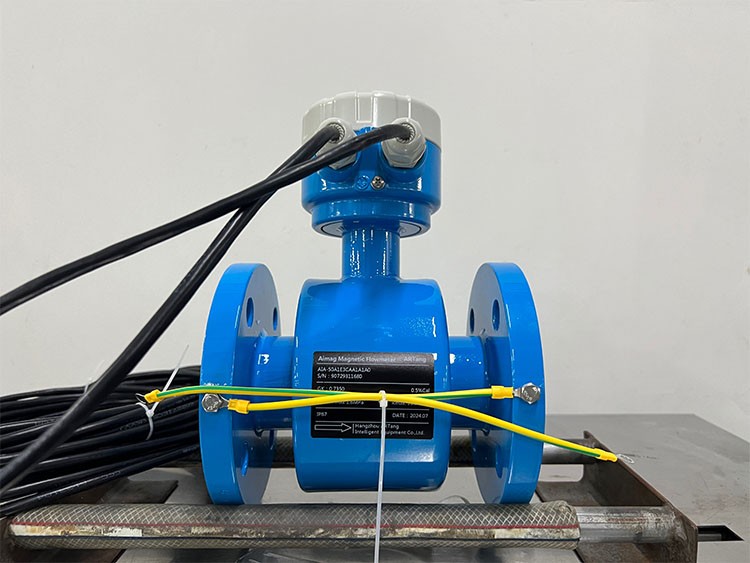

Electromagnetic Water Flow Meter

Magnetic Inductive Flow Meters

Key Features of Our Magnetic Inductive Flow Meters:

Electrode Materials: Options include stainless steel, Hastelloy, platinum, and tantalum, catering to different fluid types and process environments.

Liner Materials: Available liners include PTFE, PFA, and ceramic, allowing the ARTang to handle aggressive chemicals and high temperatures.

Flow Tube Sizes: The ARTang is available in various sizes, ranging from DN6 to DN3000, to accommodate different flow rates and pipeline diameters.

Accuracy: The flow meter provides an accuracy of ±0.2% of the measured value, ensuring reliable data for process control.

Temperature Range: The ARTang can operate in temperatures ranging from -20°C to 150°C, depending on the selected liner and electrode materials.

Pressure Rating: The flow meter is designed to withstand pressures up to 40 bar, making it suitable for high-pressure applications.

Communication Protocols: Supports Modbus, Profibus, HART, and other industrial communication standards for seamless integration into process control systems.

The measured medium must be a conductive liquid with a conductivity of generally ≥20 μS/cm. The measured medium must not contain large amounts of ferromagnetic substances or bubbles, and cannot be used for measuring gases, steam, or non-conductive media.

A Wide Range of Applications

The ARTang Magnetic Inductive Flow Meter is highly versatile and can be applied across a wide range of industries.

Chemical and Petrochemical Industry: Ideal for measuring the flow of various chemicals, including corrosive acids and bases, within manufacturing processes. Its corrosion-resistant materials ensure longevity in harsh environments.

Oil and Gas Industry: Used to monitor the flow rates of hydrocarbons, such as crude oil, natural gas liquids (NGLs), and refined products. The ARTang helps optimize fuel consumption and manage costs effectively.

Food and Beverage Industry: Suitable for measuring the flow rates of liquids in beverage production, including water, juices, and other ingredients. It ensures precise control over mixing processes for consistent product quality.

Pharmaceutical Industry: Essential for measuring and controlling the flow of purified water and other liquids in pharmaceutical manufacturing. The ARTang ensures accurate dosing and filling, contributing to product consistency and compliance with regulatory standards.

Water and Wastewater Treatment: The ARTang can be used to monitor the flow of potable water and wastewater, helping to ensure efficient treatment processes and compliance with environmental regulations.

ARTang is at the forefront of delivering exceptional magnetic flow meter solutions for different sectors. As a result of our dedication to excellence, we guarantee that every product has capabilities and features that can maximize your operational speed. While we are dedicated to maintaining our position as the industry leader in the field of magnetic flow measurement, we are also committed to conducting ongoing research and making continued technological advancements.

ARTang offers a comprehensive range of magnetic flow measurement solutions developed to meet specific industry needs. We understand that every industry has unique requirements, and our magnetic Inductive flow meters are designed to meet those specific challenges. For example, in the chemical industry, accurate flow measurements are crucial for maintaining reaction conditions and ensuring product quality. In the industrial water sector, our meters help manage and optimize water usage, supporting sustainability goals and regulatory compliance. The mining and metal processing industry relies on our robust meters to handle abrasive slurries and maintain operational efficiency. In the oil and gas sector, precise flow monitoring is essential for optimizing production and ensuring safety. The pulp and paper industry benefits from our meters’ ability to provide consistent measurements in challenging environments, ensuring smooth and efficient operations.

Factors to Consider When Choosing an Electromagnetic Water Flow Meter

When selecting an electromagnetic water flow meter for a specific application, several factors need to be considered:

Flow rate, range and accuracy requirements: Determine the anticipated flow rate, range and the required level of accuracy for your application. This will help you choose a flow meter with the appropriate specifications.

Pipe size, and compatibility: Consider the size of the pipe where the flow meter will be installed. Ensure that the flow meter is compatible with the pipe size to ensure accurate measurements.

Material compatibility, and environmental conditions: Evaluate the fluid's composition and temperature to ensure the flow meter's materials can withstand the specific environment. Corrosive or abrasive fluids may require specialized materials.

Output options and communication protocols: Consider the data output options provided by the flow meter, such as analog, digital, or wireless interfaces. Compatibility with your existing monitoring systems and communication protocols should also be assessed.

Cost and long-term investment considerations: While cost is an important factor, it should be balanced with the overall performance and reliability of the flow meter. Consider the long-term maintenance requirements and potential cost savings associated with accurate flow measurement.

Installation and Maintenance of Electromagnetic Water Flow Meters

Proper installation and regular maintenance are crucial for the optimal performance of electromagnetic water flow meters. Here are some key considerations:

Proper positioning and mounting guidelines: Follow the manufacturer's guidelines for installing the flow meter in the pipeline. Ensure that there are no obstructions or bends upstream and downstream of the flow meter that could affect the measurements.

Calibration and zero adjustment procedures: Calibrate the flow meter according to the manufacturer's recommendations to ensure accurate measurements. Zero adjustment may be required periodically to compensate for any drift.

Regular inspection and cleaning practices: Periodically inspect the flow meter for any signs of fouling, buildup, or damage. Clean the electrodes and ensure that they are free from debris to maintain accurate measurements.

Troubleshooting common installation issues: In case of unexpected readings or performance issues, consult the user manual or contact the manufacturer's technical support for troubleshooting assistance. Common issues may include improper grounding, incorrect wiring, or signal interference.

Q1: Can an electromagnetic water flow meter measure corrosive fluids?

A1: Yes, electromagnetic water flow meters can measure corrosive fluids. However, it's crucial to select a flow meter with suitable materials of construction that can withstand the corrosive properties of the fluid.

Q2: What is the typical lifespan of an electromagnetic water flow meter?

A2: The lifespan of an electromagnetic water flow meter can vary depending on factors such as the operating conditions, maintenance practices, and the specific model. With proper installation and regular maintenance, electromagnetic flow meters can last 10 to 20 years or more.

Q3: Are there any size limitations for electromagnetic water flow meters?

A5: Electromagnetic water flow meters are available in a wide range of sizes, from small diameters suitable for residential applications to large diameters for industrial and municipal applications. The size of the flow meter should be selected based on the pipe size and the anticipated flow rate for accurate measurements.