-

Date:2025-10-23

-

Page View:217

Industrial pressure sensors should not come into direct contact with high-temperature media. Prolonged exposure to high temperatures can damage the sensor. Typically, when measuring high-temperature media, pressure transmitters are equipped with stainless steel heat dissipation devices to prevent direct contact between the medium and the transmitter. Additionally, a cooling tube can be added on top of the heat dissipation device to further reduce the risk of heat damage.

High-temperature pressure sensors/transmitters use cooling element designs and can measure liquids or gases at temperatures up to 850°C. Applications include steam, food processing, and engine monitoring.

How Does an Industrial Pressure Sensor Measure High-Temperature Media?

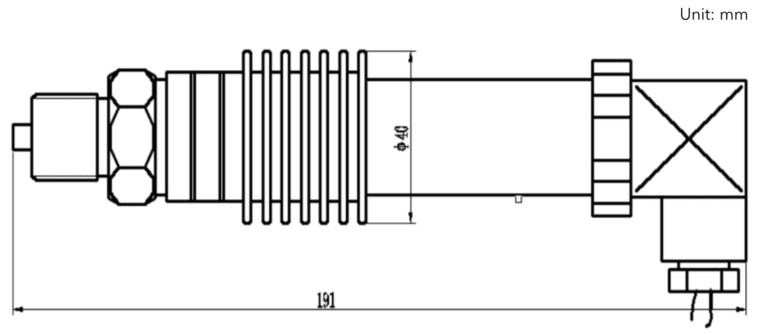

A common design approach is to incorporate mechanical cooling elements to dissipate heat, reducing the temperature near the pressure transmitter. The cooling assembly can be filled with oil and isolated from the process medium via a diaphragm.

Alternatively, the cooling assembly may include a hollow tube. The shape of the hollow tube is designed to enhance heat transfer, allowing the process medium passing through to be cooled to a much lower temperature. Cooling elements typically rely on the principle of convective heat transfer, which uses the motion of a fluid to transfer heat efficiently.

How Is an Industrial Pressure Sensor Applied in Steam Pipelines?

Pure steam pipelines have excellent mechanical strength and insulation properties. Under normal conditions, they can withstand temperatures up to 120°C. With modifications or in combination with other insulating materials, they can endure temperatures up to 180°C, making them suitable for insulation in various high- and low-temperature water pipelines. Pressure monitoring inside steam pipelines is critical, and because of the high-temperature conditions, high-temperature pressure transmitters specifically designed for such applications—like those offered by our company—are ideal.

How to Choose an Industrial Pressure Sensor for High-Temperature Environments?

Use this checklist to define your high-temperature pressure transmitter requirements: process temperature, cooling mechanism, ambient temperature, pressure range, output signal, process connection, and more.

How to Protect an Industrial Pressure Sensor in High-Temperature Conditions?

If a pressure sensor operates for long periods in a high-temperature environment without protection, its PCB circuits, components, seals, and internal mechanism can be damaged or burned. To ensure long-term reliable operation, proper protective measures are necessary:

1.If the process medium temperature exceeds 100°C and reaches up to 200°C, install a condensation coil at the pressure tap, followed by a heat sink. This allows the medium to cool through the condensation coil and then further dissipate heat via the heat sink, so the temperature at the sensor interface is greatly reduced.

2.For extremely high-temperature measurements, extend the impulse tube before connecting to the pressure sensor, or add a capillary tube with a heat sink to cool the medium before it reaches the sensor.

3.If the process medium temperature is between 70°C and 80°C, simply adding a heat sink between the pressure sensor or gauge and the pressure tap connection is sufficient. This allows the medium to cool slightly before contacting the instrument directly.

How to Choose the Right Industrial Pressure Sensor

Selecting a pressure sensor for a specific application requires considering multiple factors. Here’s a detailed guide:

Choose Based on the Properties of the Measured Medium

Corrosive Media

When measuring the pressure of corrosive fluids such as acids, bases, or saline solutions, select a pressure sensor made of corrosion-resistant materials, such as 316L stainless steel or sensors with Hastelloy housings and diaphragms.

For example, in chemical production processes monitoring acid-base neutralization reactions, standard sensors are quickly corroded and damaged. Pressure sensors with Hastelloy housings and tantalum diaphragms can operate reliably over long periods.

Viscous Media

For viscous substances like glue, paint, or syrup, diaphragm pressure sensors are recommended. They effectively isolate the viscous material, preventing it from entering the sensor, which could affect measurement accuracy or damage the sensor.

For instance, when measuring syrup pressure in food processing, using a diaphragm pressure sensor ensures accurate readings and simplifies cleaning and maintenance.

High-Temperature Media

When measuring high-temperature media such as in furnaces or boilers, use high-temperature pressure sensors. The sensor’s internal sensing element and housing must withstand extreme temperatures.

Generally, pressure sensors with ceramic sensing elements and stainless steel housings can operate normally at temperatures up to 400°C, meeting the requirements of most high-temperature applications.

Consider the Working Environment

Harsh Environments

When operating in harsh environments with heavy dust, such as mines or construction sites, choose pressure sensors with a high protection rating, such as IP65, which effectively prevent dust and water ingress.

Additionally, if flammable or explosive gases are present, select explosion-proof pressure sensors, such as intrinsically safe models, which can operate safely in hazardous environments.

Vibration and Shock Conditions

For applications involving vibration, such as automotive engine test benches, select pressure sensors with strong vibration resistance. Their internal design and mounting methods should withstand a certain level of vibration and shock, minimizing measurement errors.

Based on Signal Output and Compatibility

Signal Output Type

If downstream equipment or systems can only accept analog signals, such as some traditional industrial control panels, choose a pressure sensor that outputs a 4–20 mA analog current signal.

For digital control systems, like smart factory setups, select pressure sensors with digital outputs such as SPI or I²C, which facilitate system integration and data transmission.

Compatibility

An industrial pressure sensor should be compatible with other devices and software in the system, including power supply, communication protocols, and data acquisition equipment. In automated production lines, all devices need to work together seamlessly, so the pressure sensor must integrate well with PLCs, industrial computers, and other control equipment to ensure stable system operation.