-

Date:2025-07-14

-

Page View:368

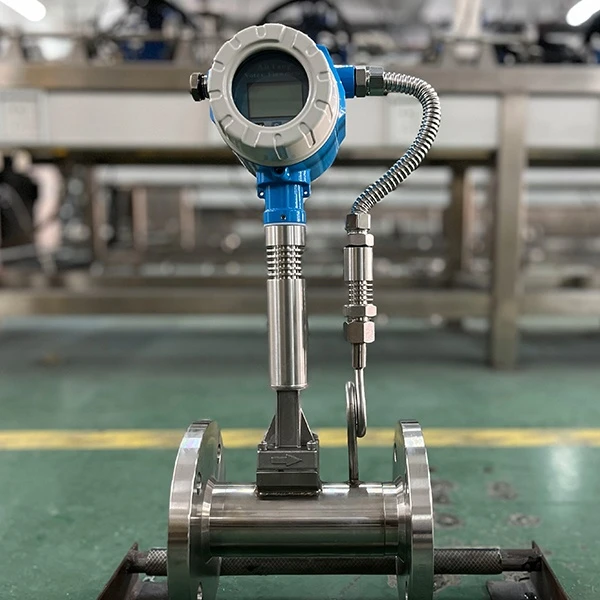

In modern industry, vortex gas flow meters are highly regarded for their excellent suitability, especially for flow measurement of gases, liquids and steam. However, it is not easy to select a vortex flow meter that meets your needs; it involves weighing multiple factors. This article will provide you with a set of systematic vortex flowmeter selection guide to help you make an informed choice to avoid the cost and efficiency loss caused by improper selection.

Clarify the measurement requirements

Before selecting the model, first of all, we should clarify the measurement requirements, including the type of medium to be measured (gas, liquid or steam), flow range, pipeline size, and measurement accuracy. Vortex flowmeter is suitable for a variety of media, but the measurement characteristics and requirements of different media are different, so you need to choose the right model and specifications.

Flow range: should ensure that the commonly used flow rate is located in the upper middle of the measurable range of the vortex flowmeter, to avoid the impact of pipeline vibration in the measurement of the lower limit. If the flow range is beyond the vortex flowmeter's measurable range, you can consider the use of shrinkage or expansion methods, but note that shrinkage may increase resistance and back pressure, and expansion may appear cavitation.

pipe size: vortex gas flow meters pipe size should be matched with the size of the pipe being measured to ensure measurement accuracy and fluid stability. At the same time, the length of the straight pipe section will also affect the stability of the fluid measurement, so it needs to be considered comprehensively when selecting the type.

Consider the characteristics of the medium

The characteristics of the measured medium are critical to the selection of vortex flow meters. The medium's temperature, pressure, density, viscosity and whether it contains impurities will affect the measurement accuracy and stability of the flow meter.

Medium temperature: vortex flowmeter is usually suitable for normal temperature, medium and high temperature range of media. If the site media temperature is higher, such as superheated steam, you may need to use other types of flow meters, such as orifice plate flowmeter.

medium pressure: nominal pressure is also an important basis for selection, it is mainly based on the installation method to divide. For example, the nominal pressure of the French card mounted vortex flowmeter for 5MPa, while the insertion of the installation type may be 6MPa, 5MPa or 0MPa.

Media characteristics: vortex flowmeter is not suitable for measuring pulsating flow, so you need to confirm whether the piping system has power mechanical equipment may produce strong pulsation, in order to avoid measurement errors caused by pulsation frequency and vortex frequency is similar. At the same time, for corrosive media, should choose corrosion-resistant flowmeter material, and consider the internal structure of the flowmeter and sealing performance.

Selection of suitable structure and material

Meter body material: carbon steel (economic), stainless steel (general purpose), special alloy (strong corrosive environment).

Sensor type: piezoelectric (general-purpose), capacitive (stronger anti-vibration interference).

Connection: flange connection (mainstream), clamping type (small diameter), threaded connection (high-pressure occasions).

Consider the installation conditions and environmental factors

The installation conditions and environmental factors of vortex gas flow meter will also affect its measurement performance. Therefore, when selecting the type, it is necessary to comprehensively consider the installation location, pipeline layout, straight pipe length, vibration conditions, electromagnetic interference and protection level and other factors.

Installation location: should ensure that the flowmeter away from strong magnetic fields and mechanical vibration to reduce external interference. At the same time, the flowmeter should be installed in the area of smooth fluid flow, avoiding close to elbows, valves and other components that interfere with the flow.

straight pipe section length: vortex gas flow meters have certain requirements for straight pipe sections, generally require the first 10D after 5D (D is the diameter of the pipeline) of the length of the straight pipe section to ensure fluid stability. If the straight pipe section is not enough, it may affect the measurement accuracy.

Protection level: the commonly used IP protection level of vortex flowmeter includes IP65, IP67 and IP68. when selecting, the appropriate protection level should be determined according to the installation location of the vortex. For example, IP65 is usually chosen for indoor installation; for outdoor location above ground, higher protection level is needed; if installed in the ditch below the outdoor ground, IP68 and separated amplifier should be chosen to prevent damage by water immersion.

Special conditions handling

Low flow rate measurement: choose low frequency vortex or with signal amplification

Multi-phase flow (e.g. liquids with air bubbles): vortex gas flow meters are not suitable, other technologies need to be considered (e.g. electromagnetic flow meters).

Pulsating flow: add buffer or damping device.

Common Misconceptions to Avoid

Misconception 1: Selection only according to the pipe diameter → The actual flow range needs to be taken as the basis, and reduce/expand the diameter if necessary.

Misconception 2: Ignore the impact of vibration → plant vibration is large need to choose vibration-resistant models or install shock absorbers.

Myth 3: Steam measurement is not compensated → Temperature and pressure compensation or external transmitter must be integrated.

Summarize the steps

List the media parameters (type, temperature, pressure, viscosity, etc.).

Calculate the operating flow range and Reynolds number.

Select the protection class (IP65/IP67) and explosion-proof requirements according to the environment.

Compare the manufacturer's selection manual and consult technical support if necessary.

Systematic evaluation through the above steps can significantly improve the accuracy of selection and stability of use. If the working conditions are complex, it is recommended to provide detailed parameters for the manufacturer to customize the solution.

Selecting the range of a vortex gas flow meter is a process that takes into account a number of factors. In practical applications, according to the specific process, equipment specifications and fluid characteristics and other factors to analyze and select, to ensure that the selected range of vortex gas flow meters to meet the actual needs, and to ensure the accuracy and reliability of the measurement.